Sustainable Electrochemical Systems: Green Foundations for Advanced Drug Development

This article provides a comprehensive overview of sustainable electrochemical systems, focusing on their transformative potential in pharmaceutical research and development.

Sustainable Electrochemical Systems: Green Foundations for Advanced Drug Development

Abstract

This article provides a comprehensive overview of sustainable electrochemical systems, focusing on their transformative potential in pharmaceutical research and development. It explores the fundamental principles of electrochemistry, detailing innovative methodologies like electro-synthesis for creating complex drug molecules without traditional catalysts. The content addresses key optimization challenges, including electrode stability and reaction scalability, crucial for industrial application. A comparative analysis evaluates the sustainability, efficiency, and economic viability of electrochemical methods against conventional processes. Tailored for researchers, scientists, and drug development professionals, this review synthesizes current advancements and future directions, highlighting the role of electrochemistry in fostering greener, more efficient pharmaceutical manufacturing.

Electrochemistry Fundamentals and the Drive for Sustainable Pharma

Electrochemical synthesis is experiencing a significant renaissance, emerging as a green and powerful approach to modern organic synthesis by utilizing electricity as a replacement for hazardous chemical oxidants and reductants [1]. This technology, with origins dating back to the work of Faraday in 1830 and Volta in 1800, represents an advancement of an ancient technology, offering a sustainable pathway for chemical transformations crucial to fields including drug development [1]. The core premise is the use of the electron as a traceless reagent, which can substantially reduce the risk, expense, and waste production associated with conventional synthetic protocols [1]. This guide details the core principles, methodologies, and future directions of sustainable electrochemical systems, providing researchers and scientists with the technical foundation to implement these techniques in both academic and industrial settings.

Core Principles and Quantitative Foundations

Fundamental Concepts and System Components

In electrochemical synthesis, redox reactions are driven by an external power source rather than traditional chemical reagents. The applied potential enables reactions to proceed along pathways away from thermodynamic equilibrium, providing access to chemical intermediates and transformations that are challenging to achieve otherwise [1]. A typical electrochemical system consists of several key components: a power supply, electrodes (anode and cathode), an electrolyte, a solvent, and a reaction cell [1].

These components can be configured in several ways, primarily through direct electrolysis, where the substrate reacts directly at the electrode surface, or indirect electrolysis, which employs a redox mediator to shuttle electrons between the electrode and the substrate [1]. Furthermore, paired electrochemical reactions maximize atom and energy economy by simultaneously utilizing both the anodic oxidation and cathodic reduction in a synergistic fashion [1].

Quantitative Analysis of Electrochemical Techniques

The selection of electrochemical method and parameters significantly influences reaction efficiency, selectivity, and sustainability. The table below summarizes key quantitative data for different electrochemical approaches.

Table 1: Comparison of Core Electrochemical Synthesis Techniques

| Technique | Primary Energy Input | Key Advantage | Typical Scale-Up Challenge | Green Chemistry Metric (Atom Economy) |

|---|---|---|---|---|

| Direct Electrolysis | Electrical Potential | Direct electron transfer, no mediator needed | Electrode fouling | Very High (Traceless reagent) [1] |

| Indirect Electrolysis | Electrical + Chemical (Mediator) | Enables difficult reactions; protects electrode | Mediator separation/recovery | High (Depends on mediator) [1] |

| Paired Electrolysis | Electrical Potential | Maximizes energy/atom economy (100% current use) [1] | Balancing anode/cathode reaction rates | Excellent (Dual product formation) [1] |

| Alternating Electrode Electrolysis (AEE) | Pulsed Electrical Potential | Prevents passivation; extends electrode life [1] | Complex process control | Very High (Traceless reagent) [1] |

| Photoelectrochemistry | Electrical + Photon Energy | Access to novel reactive intermediates [1] | Reactor design for light penetration | High (Reduces overpotential) [1] |

| Mechanoelectrochemistry | Electrical + Mechanical | Handles insoluble substrates; solvent-free [2] | Specialized reactor design | Excellent (Minimal solvent) [2] |

Performance Metrics for Industrial Application

For industrial adoption, particularly in pharmaceutical development, understanding the performance and environmental impact of electrochemical methods versus traditional synthesis is critical. The following table provides a comparative analysis based on key operational and green metrics.

Table 2: Quantitative Comparison: Electrochemical vs. Traditional Synthesis

| Parameter | Traditional Organic Synthesis | Electrochemical Synthesis | Improvement Factor / Note |

|---|---|---|---|

| Reagent Type | Chemical oxidants/reductants (e.g., MnO₂, NaBH₄) | Electrons (Traceless reagent) [1] | Eliminates stoichiometric metallic waste [1] |

| Inherent Safety | Often requires hazardous, toxic reagents | Generally milder conditions (safe, mild) [1] | Reduces risk of runaway reactions [1] |

| Reaction Control | Temperature, concentration, catalyst | Applied potential/current (precise reactivity monitoring) [1] | Fine-tuned selectivity control [1] |

| Energy Efficiency | Thermal activation (often high T) | Direct electrical activation (often ambient T) [1] | Potential for lower energy input |

| Scalability | Well-established for batch processing | Scalable in flow microreactors [1] | Continuous processing enhances sustainability [1] |

| Functional Group Tolerance | Can be low for strong oxidants/reductants | Potentially high with controlled potential | Enables late-stage functionalization in APIs |

Experimental Protocols and Methodologies

General Protocol for a Batch Electrolysis Reaction

This protocol provides a foundational methodology for conducting a standard batch electrochemical reaction, adaptable for various transformations such as the anodic oxidation of organics or cathodic reductions [1] [3].

- Reaction Setup: Assemble a standard batch electrolysis cell (divided or undivided based on the need to separate anolyte and catholyte). The cell typically includes the main chamber, electrodes, a magnetic stir bar, and ports for a reference electrode (if used) and gas inlet/outlet [1].

- Electrode Preparation: Select appropriate electrode materials (e.g., glassy carbon, platinum, or boron-doped diamond for a broad potential window) [1]. Clean the electrodes according to standard procedures (e.g., polishing with alumina slurry for solid electrodes) and place them in the cell, ensuring a proper inter-electrode gap.

- Solution Preparation: Charge the cell with the solvent (e.g., acetonitrile, DMF) and supporting electrolyte (e.g., LiClO₄, NBu₄PF₆, 0.1 M typical concentration). Add the substrate to the solution. If using a divided cell, ensure the compartments are separated by an ion-permeable membrane [1].

- Pre-Reaction Check: Purge the reaction mixture with an inert gas (e.g., N₂ or Ar) for 10-15 minutes to remove dissolved oxygen, especially for reduction reactions. Begin stirring the mixture.

- Initiation of Electrolysis: Connect the electrodes to the potentiostat/galvanostat. Apply the predetermined constant current (CC) or constant potential (CP). Record the initial voltage/current and begin timing the reaction.

- Reaction Monitoring: Monitor the reaction progress by tracking the charge passed (in Faradays) and/or by using in-line analytical techniques such as HPLC, GC, or TLC [1].

- Work-up: Once the reaction is complete (e.g., current drops significantly or target charge is passed), disconnect the power supply. Separate the electrodes from the reaction mixture.

- Product Isolation: The reaction mixture is then subjected to standard work-up procedures. This typically involves dilution with water and extraction with an organic solvent. A key step is the removal of the dissolved electrolyte, which can often be achieved by washing with water or through chromatography [1].

- Product Analysis: Identify and characterize the product using standard analytical methods (NMR, IR, MS) and determine yield and purity.

Specific Protocol for Mechanochemically Mediated Electrosynthesis

This protocol details the emerging hybrid technique that combines mechanical milling with electrochemistry, ideal for substrates with low solubility, enabling reactions under minimal solvent conditions [2].

- Specialized Equipment Setup: Utilize a specifically designed two-electrode Mechano-Electrochemical Cell (MEC) integrated into a ball mill apparatus. The MEC must be connected to an external power source [2].

- Cell and Milling Media Preparation: Load the MEC with the electrode materials (optimized for size and interelectrode gap) and the appropriate milling balls. The electrode material and size are critical optimization parameters [2].

- Reaction Charging: Add the solid substrate(s) and a minimal amount of solvent (if any) directly into the MEC chamber. A stoichiometric amount of electrolyte is added, often in solid form.

- Initiation: Simultaneously start the mechanical milling process and apply the controlled electrical potential from the external power source.

- Process Control: The reaction proceeds under the combined action of mechanical impact and shear forces and the applied electrochemical potential. Parameters like milling frequency, applied potential, and reaction time are controlled [2].

- Completion and Work-up: After the set reaction time, stop both milling and electrical input. The solid reaction mixture is then collected from the MEC.

- Product Isolation: The product is typically isolated by washing the solid residue with a solvent to dissolve the organic products, followed by filtration to remove the milling media and any insoluble salts/electrolyte. Further purification is achieved via standard techniques like recrystallization or chromatography [2].

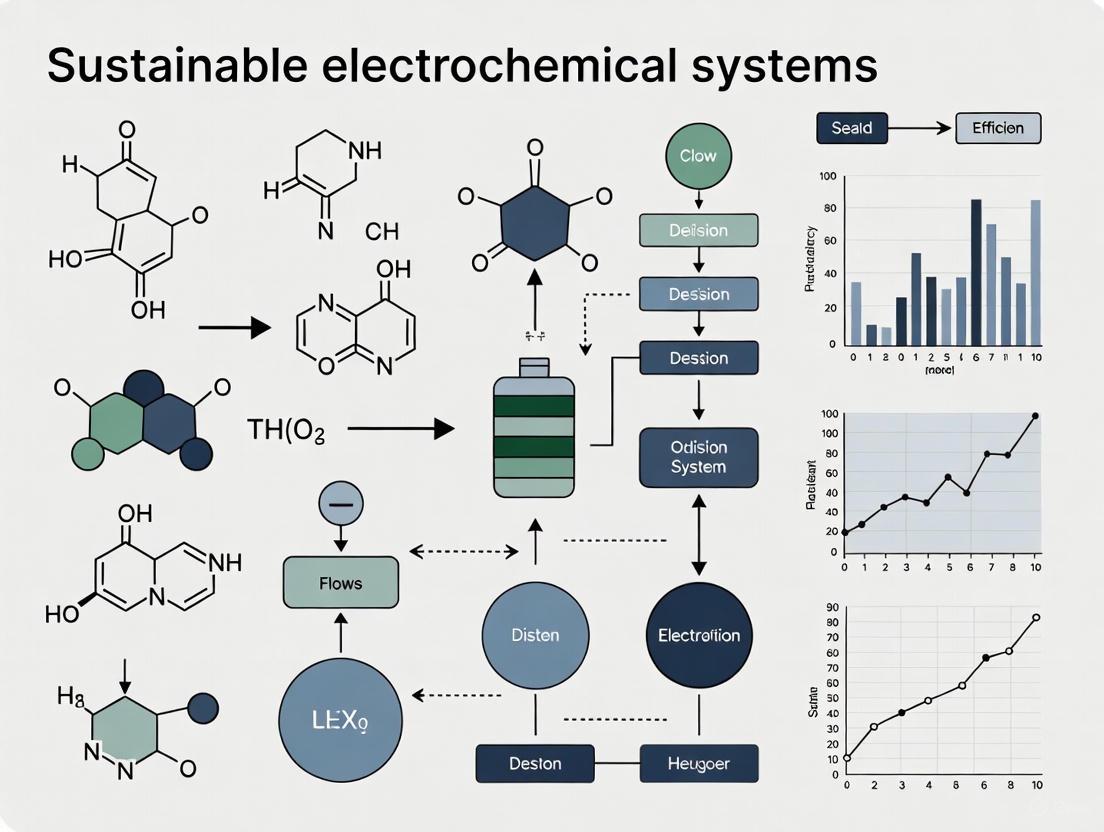

Visualization of Workflows and Pathways

Logical Workflow for Method Selection

The following diagram outlines a decision-making pathway for selecting the appropriate electrochemical technique based on reaction goals and substrate properties.

Experimental Setup and Reaction Pathway

This diagram illustrates the core components of a batch electrochemical cell and the coupled redox processes at the electrodes for a generic paired electrolysis.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of electrochemical synthesis requires careful selection of components. The table below details key materials and their functions in constructing efficient electrochemical systems.

Table 3: Essential Materials and Reagents for Electrochemical Synthesis

| Item Category | Specific Examples | Function & Rationale | Key Selection Criteria |

|---|---|---|---|

| Electrode Materials (Anode) | Boron-Doped Diamond (BDD), Platinum, Graphite [1] | Site for oxidation; determines reaction pathway & overpotential. BDD offers a wide potential window [1]. | Conductivity, stability under oxidizing conditions, cost, and potential window. |

| Electrode Materials (Cathode) | Glassy Carbon, Lead, Zinc [1] | Site for reduction; critical for hydrogen evolution reaction (HER) overpotential. | Conductivity, stability under reducing conditions, and HER overpotential. |

| Solvents | Acetonitrile, DMF, MeOH [1] | Dissolves substrate and electrolyte; determines electrochemical window. | Polarity, electrochemical stability (inert window), and ability to dissolve electrolyte. |

| Electrolytes | LiClO₄, NBu₄PF₆, NBu₄BF₄ [1] | Provides ionic conductivity in the solution; does not participate in reaction. | Solubility in solvent, electrochemical stability, and ease of removal during work-up. |

| Redox Mediators | Halide salts, TEMPO, metal complexes [1] | Shuttles electrons indirectly in challenging direct electrolyses. | Redox potential matching the desired reaction, stability in oxidized/reduced forms. |

| Cell Designs | Divided Cell (H-cell), Undivided Cell, Flow Microreactors [1] | Divided cell separates anolyte/catholyte; undivided is simpler; flow enables scalability [1]. | Need to prevent product crossover at counter electrode and scalability requirements. |

The Sustainability Imperative in Pharmaceutical Manufacturing

The global pharmaceutical industry faces a critical sustainability imperative, driven by environmental responsibility, economic pressure, and evolving regulatory landscapes. Accounting for nearly 5% of global greenhouse gas emissions—55% higher than the automotive industry—the sector is undergoing fundamental transformation [4]. By 2025, pharmaceutical companies are projected to spend $5.2 billion annually on environmental programs, representing a 300% increase from 2020 [5]. This investment reflects a strategic recognition that sustainable practices yield competitive advantages through 15% lower production costs, enhanced brand value, and improved talent attraction [5]. Within this broader context, sustainable electrochemical systems emerge as particularly promising technologies for reducing environmental impact while maintaining manufacturing efficiency and product quality.

The pressure for transformation originates from multiple stakeholders: regulators demanding stricter environmental standards, patients seeking sustainable options, and investors increasingly applying environmental criteria to funding decisions [5]. Furthermore, with pharmaceutical carbon emissions projected to triple by 2050 without intervention, the industry faces urgent calls to action [4]. This technical guide examines the implementation frameworks, electrochemical innovations, and metrics necessary for pharmaceutical manufacturers to successfully navigate this sustainability imperative.

Current Sustainability Landscape and Key Performance Metrics

Quantitative Environmental Impact of Pharmaceutical Manufacturing

Table 1: Key Environmental Impact Metrics for the Pharmaceutical Industry

| Metric Category | Current Impact Level | Comparative Context | 2030 Projection |

|---|---|---|---|

| Greenhouse Gas Emissions | 4.4-5% of global total [4] | 55% higher than automotive industry [4] | Expected to triple by 2050 without intervention [4] |

| Plastic Waste | 5.5 million tons of lab plastics to landfills annually [4] | Medicines account for 25% of NHS carbon footprint [4] | Increasing with current practices |

| Water Consumption | Significant reduction potential (up to 50%) with advanced technologies [4] | Sanofi achieved 18% reduction in water withdrawals [4] | 15-20% reduction targets for major manufacturers |

| Financial Investment | $5.2 billion/year on environmental programs [5] | 300% increase from 2020 [5] | Expected to grow as regulations tighten |

Emission Scopes and Reduction Targets

Pharmaceutical companies face distinct challenges across different emission categories:

Scope 1 & 2 Emissions: Direct and indirect emissions from operations. Companies like Merck aim for carbon neutrality in these scopes by 2025 through renewable energy transition, sustainable building standards, and carbon offsets [4]. Industry leaders including Roche and Novo Nordisk already operate on 100% renewable energy [4].

Scope 3 Emissions: Comprising approximately 80% of pharmaceutical emissions, these indirect emissions from supply chains represent the most significant challenge [4]. The Association of the British Pharmaceutical Industry (ABPI) notes companies are now assessing entire medicine lifecycles to address these emissions [4]. Seven global companies (AstraZeneca, GSK, Merck KGaA, Novo Nordisk, Roche, Samsung Biologics, and Sanofi) have announced joint action to accelerate net zero health systems, including common frameworks to reduce greenhouse gases in phase 2 and 3 clinical trials [4].

Sustainable Manufacturing Frameworks and Implementation Strategies

Core Sustainability Pillars in Pharmaceutical Manufacturing

Table 2: Strategic Implementation Framework for Pharmaceutical Sustainability

| Strategic Pillar | Implementation Technologies | Expected Outcomes | Case Study Examples |

|---|---|---|---|

| Green Chemistry & Synthesis | Electro-organic synthesis, solvent-free manufacturing, biocatalysts | 19% waste reduction, 56% productivity improvement [4] | Pfizer, Boehringer Ingelheim adopting green chemistry; 30% emission reduction at Novartis [5] [4] |

| Energy Efficiency & Renewables | Solar panels, energy audits, smart meters, machinery optimization | Lower energy bills, reduced on-site emissions | GlaxoSmithKline systematic energy management; Novartis 30% emission cut [5] |

| Waste Reduction & Circular Economy | Lean production, recycling programs, digital twins, IoT | 28% carbon decrease (Cipla); 20% operational waste reduction (Johnson & Johnson) [5] [4] | Johnson & Johnson recycling initiatives for plastics and metals [5] |

| Sustainable Supply Chains | Local sourcing, digital platforms, blockchain tracking, green suppliers | Reduced transport emissions, improved resilience | Evonik implementing 'handprint' metric for socioeconomic impact [6] |

| Water Stewardship | Reverse osmosis, membrane filtration, recycling systems | Up to 50% consumption reduction in some facilities [4] | Sanofi water recycling surpassing 2030 targets; Novartis reverse osmosis in Singapore [4] |

Electrochemical Systems as Sustainable Synthesis Solutions

Electro-organic synthesis represents a transformative approach to sustainable pharmaceutical manufacturing by using electricity rather than stoichiometric reagents to drive chemical reactions [7]. This methodology aligns with multiple green chemistry principles while enabling novel synthetic pathways.

Fundamental Advantages of Electrochemical Systems:

- Waste Reduction: Eliminates need for stoichiometric oxidants and reductants, significantly decreasing waste generation [7]

- Novel Reactivity: Enables access to reactive intermediates difficult to obtain via conventional approaches [7]

- Energy Efficiency: Direct electron transfer can be more efficient than multi-step chemical redox processes

- Safety Profile: Often operates under milder conditions with reduced use of hazardous chemicals

Key Technical Considerations for Implementation:

Electrochemical systems require addressing several technical factors to ensure successful implementation in pharmaceutical manufacturing contexts:

- Reaction Scope and Compatibility: While electrochemical reaction scope has expanded, limitations remain compared to traditional methods, particularly for substrates with sensitive functional groups (cyano- or nitro-groups sensitive to reduction) [7]

- Scalability Challenges: Issues including electrode fouling, heat management, and mass transfer limitations must be addressed through reactor design [7]

- Electrode Materials: Development of cost-effective, durable electrodes that withstand diverse reaction conditions remains an ongoing research area [7]

- Solvent Systems: Selection of greener solvents is critical as solvents constitute a major portion of environmental impact [7]

Electro-organic Synthesis: Experimental Protocols and Workflows

Core Experimental Setup for Pharmaceutical Electro-synthesis

Reactor Configuration Selection: Electrochemical reactions can be performed in either batch or flow reactors, each with distinct advantages for pharmaceutical applications. Batch reactors are typically used for initial small-scale optimization (≤100 mg), while flow reactors enable better heat transfer, reduced interelectrode distances, and potential for continuous processing [7]. For medium-scale reactions (100-1000 mg), batch scale-out approaches with increased electrode surface area are often employed [7].

Essential Experimental Parameters:

- Current Density: Typically optimized between 5-50 mA cm⁻², with higher current densities desirable for scale-up but potentially impacting functional group tolerance [7]

- Electrode Materials: Selection based on reaction type (oxidation/reduction) and compatibility with reaction media; common options include platinum, carbon (graphite, BDD), or specialized alloys [7]

- Electrolyte System: Supporting electrolytes (e.g., LiClO₄, NBu₄PF₆) at concentrations of 0.1-0.5 M to ensure conductivity; recent advances utilize chiral electrolytes for enantioselective synthesis [8]

- Solvent Selection: Prioritization of greener solvents (MeCN, EtOH, water) over halogenated solvents, with minimization of additives like HFIP [7]

Workflow for Asymmetric Electro-synthesis of Chiral Pharmaceutical Intermediates

Recent research demonstrates the use of chiral supporting electrolytes to achieve enantioselective electrochemical synthesis, addressing a significant challenge in pharmaceutical manufacturing [8]. The following workflow outlines the experimental protocol for this approach:

Detailed Experimental Protocol:

Table 3: Research Reagent Solutions for Asymmetric Electro-synthesis

| Reagent/Material | Specification | Function in Reaction | Notes & Alternatives |

|---|---|---|---|

| Chiral Electrolyte | Custom-synthesized chiral salt (0.3M) | Creates chiral environment at electrode interface; induces enantioselectivity | Cornell methodology uses electrolytes as chiral inducers [8] |

| Working Electrode | Carbon/graphite felt (3D) | High surface area electrode; improves selectivity at lower current density | Alternative: Boron-doped diamond (BDD) for oxidation reactions [7] |

| Counter Electrode | Platinum mesh/mesh | Stable counter electrode for completing circuit | Alternative: Carbon electrodes for cost-sensitive applications |

| Reference Electrode | Ag/AgCl (non-aqueous) | Provides potential reference in non-aqueous systems | Alternative: SCE with appropriate salt bridge |

| Solvent System | MeCN/water mixture | Green solvent selection; maintains conductivity | Alternative: Ethanol/water for greener profile |

| Supporting Salt | LiClO₄ or NBu₄PF₆ (0.1M) | Enhances solution conductivity without chiral induction | Required even with chiral electrolyte for optimal performance |

Step-by-Step Experimental Procedure:

Electrochemical Cell Assembly: Set up undivided cell with electrode configuration specified above. Interelectrode distance should be minimized (2-5 mm) to reduce resistance [7].

Solution Preparation: Dissolve substrate (0.1M final concentration) and chiral supporting electrolyte (0.3M) in degassed solvent system (MeCN/water 4:1). Add supporting salt (0.1M) if needed for enhanced conductivity.

Reaction Execution: Apply constant potential (determined by CV studies, typically -2.0V to +2.0V vs. reference) under inert atmosphere with stirring. Monitor current decay throughout reaction.

Reaction Monitoring: Track conversion via TLC, HPLC, or LC-MS. Typical reaction times range from 2-24 hours depending on scale and current density.

Workup Procedure: Post-reaction, remove electrodes and extract product with appropriate solvent. Remove electrolyte through aqueous extraction or chromatography.

Product Analysis: Determine yield, enantiomeric excess (chiral HPLC or SFC), and structural confirmation (NMR, MS).

Technical Considerations for Success:

- The chiral electrolyte becomes concentrated near the electrode surface with opposite charge, enhancing chiral induction [8]

- Molecular dynamics simulations can optimize electrolyte-substrate interactions prior to experimental work [8]

- This approach demonstrates broader applicability across reaction types due to universal presence of electrolytes at electrode-solution interfaces [8]

Advanced Electrochemical Engineering and System Design

Scalability Solutions for Industrial Implementation

Scaling electrochemical processes from laboratory to industrial scale presents unique engineering challenges that require specialized reactor designs:

Flow Reactor Systems: Flow electrochemical reactors offer significant advantages for scale-up, including improved heat transfer, reduced interelectrode gaps, and continuous processing capabilities [7]. Single-pass or recirculating setups enable higher throughput while maintaining control over reaction parameters.

Specialized Reactor Designs for Challenging Substrates:

- Rotating Cylinder Electrodes: Effectively handle solids/slurries, addressing a significant limitation of many commercial electrochemical reactors when processing poorly soluble pharmaceutical intermediates [7]

- Taylor Vortex Reactors: Decouple mass transfer from residence time, providing enhanced mixing and transfer rates [7]

- Bipolar Electrode Systems: Enable multiple reaction sites within a single reactor configuration, improving space-time yields [7]

Mass Transfer Considerations: Appropriate reactor design must account for mass transfer characteristics, particularly when scaling reactions. The limiting current expression for power-law fluids differs significantly from Newtonian fluids, requiring careful calculation of reactor dimensions and operating parameters [9]. Electrochemical impedance spectroscopy serves as a valuable tool for real-time, non-destructive monitoring of mass transport phenomena in these systems [9].

Electrochemical Reactor Design Architecture

Key Engineering Principles for Scalable Electrochemical Systems:

Electrode Design: Gas diffusion electrodes require optimal current collector positioning to minimize potential drops; a dimensionless factor can determine maximum distance between collectors based on material properties and current density [9]

Mass Transfer Optimization: Non-Newtonian fluid behavior significantly impacts electrochemical performance, requiring derived limiting current expressions for power-law fluids in specific electrode configurations [9]

Mediator Systems: Strategic use of mediators (e.g., nitroxyl radicals, NaBr) enables reactions at lower potentials, expands functional group tolerance, reduces electrode fouling, and allows higher current densities [7]

Sustainability Assessment and Future Perspectives

Emerging Metrics: From Carbon Footprint to Handprint Analysis

While traditional sustainability metrics focus on environmental impact reduction, the emerging "handprint" concept quantifies positive socioeconomic benefits of pharmaceutical manufacturing practices [6]. Pioneered by the WifOR Institute and implemented by companies like Evonik, this metric assesses:

- Health Benefits: Economic value created through healthier, more productive populations

- Social Impact: Broader socioeconomic contributions beyond environmental footprint

- Economic Value Creation: Monetization of positive impacts alongside cost analysis

This approach provides a more comprehensive sustainability assessment, balancing environmental footprint with demonstrated social value [6]. For example, Evonik has applied the handprint methodology to evaluate the socioeconomic benefits of PhytoChol, an ingredient in mRNA vaccine lipid nanoparticles [6].

Integration of Artificial Intelligence in Sustainable Bioprocessing

AI and machine learning play increasingly important roles in optimizing sustainable pharmaceutical manufacturing:

- Process Optimization: AI systems can reduce energy consumption by up to 20% in manufacturing facilities through predictive modeling and real-time adjustment of parameters [4]

- Waste Reduction: Digital lean principles combined with AI have enabled companies like Cipla to achieve 28% decreases in carbon emissions [4]

- Chemical Reaction Optimization: AI and machine learning predict and optimize chemical reactions for sustainability, contributing to documented 19% waste reduction and 56% productivity improvements in green chemistry applications [4]

However, the environmental footprint of AI systems themselves must be considered, including substantial electricity and water consumption, as well as mineral sourcing concerns [4].

Future Outlook and Research Directions

The transition to sustainable pharmaceutical manufacturing will be shaped by several key developments:

- Electrochemical Innovation: Advances in enantioselective electrochemistry, mediator development, and reactor design will expand electrochemical applications in pharmaceutical synthesis [7] [8]

- Circular Economy Integration: Increased focus on waste-to-commodity conversion, process intensification, and biodegradable materials will drive circularity [4] [10]

- Policy Alignment: Regulatory frameworks like the Corporate Sustainability Reporting Directive (CSRD) will mandate comprehensive ESG reporting, including all emission scopes, starting in 2025 [5]

- Advanced Materials: Bio-based polymers (currently 43.6% of sustainable bioprocessing materials market) and compostable plastics will increasingly replace conventional materials [10]

Electro-organic synthesis represents a particularly promising pathway, with potential to significantly reduce waste generation while enabling novel synthetic routes to complex pharmaceutical molecules [7]. As electrochemical methodologies become more accessible and scalable, they offer a viable approach for pharmaceutical manufacturers to achieve sustainability targets without compromising efficiency or product quality.

The transition to sustainable industrial processes is a cornerstone of the global effort to mitigate climate change and resource depletion. Within this framework, electrochemical systems have emerged as a transformative technology, offering a pathway to decarbonize chemical manufacturing and waste management. This whitepaper examines a core advancement in the field: the development of electrochemical processes that eliminate the need for precious metal catalysts and significantly reduce waste generation. By leveraging innovative materials and system designs, these processes enhance economic viability and environmental performance, moving key industries toward a circular economy model. The integration of carbon-based catalysts and innovative cell designs enables these systems to operate with high efficiency under mild conditions, reducing both capital expenditure and operating costs while minimizing environmental impact [11]. This paper details the underlying mechanisms, presents quantitative performance data, and provides reproducible experimental methodologies that underpin this technological shift.

The Technological Shift in Catalysis and System Design

Traditional industrial electrochemistry often relies on catalysts containing precious metals like platinum, iridium, and ruthenium. While effective, these materials are scarce, expensive, and subject to supply chain volatility, rendering processes economically fragile and less sustainable. The paradigm shift involves replacing them with earth-abundant alternatives and redesigning system architecture to valorize waste streams.

A primary innovation is the use of low-cost carbon-based catalysts. In the electrochemical conversion of nitric oxide (NO) to nitric acid (HNO₃), researchers have successfully employed carbon catalysts for the oxidation reaction, completely avoiding precious metals. This system pairs the carbon catalyst with a single-metal oxygen reduction catalyst, achieving high efficiency without chemical additives or costly purification steps [11]. The carbon catalyst provides a high-surface-area, conductive matrix that facilitates the NO oxidation reaction with high selectivity and minimal degradation.

Concurrently, advances in electrorefining for metal recycling demonstrate a system-level approach to waste reduction. This process purifies metals from complex recycled sources, such as electronic waste, by using an electrical current to drive the selective dissolution and deposition of target metals. The process achieves purity levels exceeding 99.9% for copper while concentrating valuable impurities like gold and silver for separate recovery, transforming waste into a resource [12]. The selectivity of electrorefining prevents the dissolution of less noble metals and allows for the collection of precious metals from anode slimes, creating additional revenue streams and closing the material loop.

Furthermore, novel electrolytic cell designs and membrane technologies are critical. For instance, in the electrochemical production of ethylene glycol, researchers developed a system featuring a specialized membrane that creates a pH difference on each side. This design enables the simultaneous production of the chemical and the capture of carbon dioxide within a single electrochemical system, tackling emissions while generating a valuable product [13]. Such integrated designs exemplify process intensification, where multiple unit operations are combined into a single, more efficient step, thereby reducing energy consumption, material usage, and physical footprint.

Quantitative Analysis of Advantages

The advantages of these new-generation electrochemical systems can be quantified across several key performance indicators, including environmental impact, economic efficiency, and resource utilization.

Table 1: Comparative Analysis of Electrochemical Processes for Chemical Synthesis

| Process Metric | Traditional Thermo-chemical Process | Advanced Electrochemical Process | Improvement / Key Data |

|---|---|---|---|

| Energy Consumption | High; e.g., 22.6 GJ/tonne for ethylene glycol [13] | Low; e.g., 10 GJ/tonne for ethylene glycol [13] | >50% reduction in energy use |

| CO₂ Emissions | Significant; e.g., 1.2 tonnes CO₂/tonne ethylene glycol [13] | Minimal; e.g., 0.13 tonnes CO₂/tonne ethylene glycol [13] | ~90% reduction in direct emissions |

| Catalyst Cost & Impact | Precious metals (Pt, Ir) | Earth-abundant carbon-based or single-metal catalysts [11] | Eliminates precious metal dependency, reduces cost |

| Waste Valorization | CO₂ and NO released as waste gases | CO₂ and NO captured and converted into valuable products [13] [11] | Transforms waste liabilities into chemical feedstocks |

| Process Integration | Multiple separate unit operations | Coupled reactions in a single system (e.g., production + capture) [13] | Reduces infrastructure, improves intensification |

Table 2: Performance Metrics in Electrorefining for Metal Recycling

| Performance Metric | Typical Data | Significance |

|---|---|---|

| Metal Recovery Rate | Up to 99.8% for silver, 99.7% for copper [14] | Maximizes resource extraction from waste streams |

| Product Purity | Exceeds 99.9% for copper; 99.99% achievable [12] | Produces high-value, electrical-grade metals |

| Energy Efficiency | 200-300 kWh/t for copper electrorefining [12] | Substantially lower than primary extraction |

| Acid Consumption | Reduced via in-process regeneration [12] | Creates a more closed-loop, less wasteful system |

| Co-Product Recovery | Concentrates Au, Ag, Pt in anode slimes [12] | Creates additional revenue streams from "impurities" |

The data demonstrates that modern electrochemical systems are not merely incremental improvements but represent a fundamental redesign of process engineering. The significant reduction in energy consumption and greenhouse gas emissions directly addresses the climate impact of the chemical and metallurgical sectors. Furthermore, the ability to achieve high-purity product recovery from waste streams, all while avoiding costly precious metals, establishes a powerful economic and environmental case for their adoption.

Detailed Experimental Protocols

To facilitate replication and further research, this section outlines detailed methodologies for two key experiments that exemplify the elimination of precious metals and waste reduction.

Protocol 1: Electrochemical Synthesis of Nitric Acid from Nitric Oxide Waste Gas

This protocol describes the direct conversion of a harmful pollutant (NO) into a valuable chemical product (HNO₃) using a carbon-based catalyst, avoiding precious metals [11].

4.1.1 Research Reagent Solutions

Table 3: Essential Materials for NO to HNO₃ Electrolysis

| Item | Function / Specification |

|---|---|

| Carbon-based Catalyst | Working electrode material for NO oxidation. Requires high surface area and electrical conductivity. |

| Single-Metal ORR Catalyst | Cathode catalyst for the Oxygen Reduction Reaction (e.g., based on Ni or Fe). Must be non-precious. |

| Gas Diffusion Electrode (GDE) | Electrode architecture to facilitate tri-phase (gas/liquid/solid) contact for high-efficiency NO oxidation. |

| Nafion Membrane | Proton exchange membrane to separate anode and cathode compartments. |

| 0.1 M Aqueous H₂SO₄ | Acidic electrolyte solution. |

| Nitric Oxide Gas Feed | Reactant source; experiments can use pure NO or diluted streams (e.g., 500-2000 ppm in N₂) to simulate flue gas. |

4.1.2 Experimental Workflow

- Electrolytic Cell Assembly: Construct a two-compartment electrochemical cell separated by a Nafion membrane. The anode compartment is fitted with the carbon-based gas diffusion electrode. The cathode compartment houses the single-metal Oxygen Reduction Reaction (ORR) catalyst.

- System Preparation: Fill both cell compartments with the 0.1 M H₂SO₄ electrolyte. Purge the anode chamber with an inert gas (e.g., N₂) to establish an inert atmosphere.

- Electrochemical Operation: Switch the anode gas feed from N₂ to the NO stream. Apply a constant current or potential to the cell. Maintain the system at near-ambient temperature and pressure (e.g., 25°C, 1 atm).

- Product Analysis and Quantification:

- Liquid Product: Periodically sample the electrolyte from the anode compartment. Analyze for nitrate/nitrite concentration using techniques such as Ion Chromatography (IC) or UV-Vis spectrophotometry (e.g., using the cadmium reduction method).

- Faradaic Efficiency Calculation: Calculate the Faradaic Efficiency (FE) for HNO₃ production using the formula:

FE = (n * F * C * V) / (I * t) * 100%, wherenis the number of electrons transferred per NO molecule (3 for NO to HNO₃),Fis the Faraday constant,Cis the concentration of HNO₃ produced,Vis the electrolyte volume,Iis the current, andtis the time. - Product Purity: The concentration and purity of the generated HNO₃ can be determined by titrimetric methods and IC analysis of anionic contaminants.

Diagram 1: NO to HNO3 Experiment Workflow

Protocol 2: Electrorefining for High-Purity Metal Recovery from E-Waste

This protocol details the electrorefining process for purifying copper from dissolved electronic waste leachate, showcasing high recovery rates and the concentration of precious metals for subsequent recovery [12].

4.2.1 Research Reagent Solutions

Table 4: Essential Materials for Metal Electrorefining

| Item | Function / Specification |

|---|---|

| Leachate Solution | Feed solution from processed e-waste, containing target metal ions (e.g., Cu²⁺) and impurities (e.g., Ni²⁺, Au³⁺). |

| Copper Sulfate & Sulfuric Acid Electrolyte | Standard electrolyte for copper electrorefining. Provides Cu²⁺ ions and high conductivity. |

| Anode | Impure copper (e.g., from casted e-waste leachate solids). |

| Cathode | Starter sheet of pure copper or permanent stainless-steel cathode. |

| Electrorefining Cell | Temperature-controlled tank with electrode holders and provisions for anode slime collection. |

| DC Power Supply | Provides controlled current for the electrorefining process. |

4.2.2 Experimental Workflow

- Electrolyte and Electrode Preparation: Prepare the electrolyte (e.g., 40 g/L Cu²⁺ and 180 g/L H₂SO₄) and heat it to the operating temperature (typically 55-65°C). Secure the impure copper anode and the pure copper cathode in the electrorefining cell, ensuring a precise and consistent electrode gap.

- Electrorefining Operation: Connect the electrodes to a DC power supply and operate at a constant current density (e.g., 200-300 A/m²). Monitor the cell voltage throughout the process. The process is run for a set duration (e.g., 5-10 days) to achieve substantial cathode growth.

- Process Monitoring and Control: Regularly inspect for and correct any short circuits caused by nodular growth or bent electrodes. Monitor electrolyte composition and adjust as needed to maintain optimal Cu²⁺ and acid concentrations.

- Product Recovery and Analysis:

- Cathode Harvesting: Remove the cathode at the end of the cycle. The deposited copper is stripped and weighed.

- Purity Analysis: Analyze the cathode copper for purity using techniques like Inductively Coupled Plasma Mass Spectrometry (ICP-MS) to quantify impurity levels.

- Anode Slime Collection and Processing: Collect the insoluble slimes from the bottom of the cell. This slime is further processed to recover precious metals like gold and silver, often through leaching and a separate, smaller-scale electrorefining step.

Diagram 2: Metal Electrorefining Workflow

The advancement of electrochemical systems that eliminate precious metals and minimize waste represents a critical nexus of sustainability and economic pragmatism. The experimental data and protocols presented confirm that through the strategic use of carbon-based catalysts, innovative cell designs, and process intensification, it is possible to decouple chemical production and metal recovery from resource-intensive and polluting paradigms. These technologies directly contribute to a circular economy by converting waste streams into valuable products, using less energy, and avoiding critical material dependencies. As research continues to enhance the efficiency, scalability, and robustness of these systems, their adoption will be instrumental in building a more sustainable and resilient industrial base. The path forward requires continued investment in fundamental research, coupled with cross-sector collaboration to translate these promising laboratory successes into widespread industrial practice.

Electrochemical Cell Components and Their Functional Roles

Electrochemical cells are fundamental devices that convert chemical energy into electrical work and vice versa, playing a critical role in sustainable energy technologies. These systems are of enormous industrial and fundamental significance, with applications ranging from energy storage in batteries to clean energy technologies like electrochemical hydrogen compression [15] [16]. Within the framework of sustainable electrochemical systems research, understanding the precise function of each cell component is essential for developing innovative processes for the sustainable production of electricity, fuels, and chemicals [17]. These processes must be scalable, environmentally benign, reduce greenhouse gas production, and utilize renewable resources to align with global decarbonization goals [17] [16].

This technical guide provides a comprehensive analysis of electrochemical cell components and their functional roles, with particular emphasis on their application in sustainable energy systems. The content is structured to serve researchers, scientists, and technology developers working toward advanced electrochemical technologies that support climate change mitigation.

Fundamental Principles of Electrochemical Cells

Electrochemical cells operate based on redox (reduction-oxidation) reactions where chemical energy is converted to electrical energy, or electrical energy drives chemical transformations. In these systems, oxidation occurs at the anode (releasing electrons), and reduction occurs at the cathode (consuming electrons) [15]. The flow of electrons through an external circuit creates useful electrical work, while the flow of ions through an electrolyte maintains charge balance within the cell [15].

The thermodynamic driving force of electrochemical cells is quantified by the Gibbs free energy change (ΔG), which relates to the cell potential (E) through the fundamental equation: ΔG = -nFE, where n is the number of electrons transferred and F is Faraday's constant [16]. This relationship forms the basis for calculating the theoretical energy conversion efficiency in systems such as batteries, fuel cells, and electrochemical compressors [16].

Core Components of Electrochemical Cells

Component Architecture and Functional Relationships

The following diagram illustrates the fundamental architecture and functional relationships between core components in a typical electrochemical cell:

Quantitative Analysis of Component Properties

Table 1: Core Electrochemical Cell Components and Their Functional Roles

| Component | Primary Function | Critical Properties | Common Materials |

|---|---|---|---|

| Anode | Site of oxidation reaction (electron release) | High electrical conductivity, catalytic activity, stability | Lithium, sodium, graphite, platinum, zinc [15] [18] |

| Cathode | Site of reduction reaction (electron consumption) | High electrical conductivity, catalytic activity, structural stability | Metal oxides (LiCoO₂, LiFePO₄), sulfur, oxygen [18] |

| Electrolyte | Medium for ion transport between electrodes | High ionic conductivity, electronic insulation, electrochemical stability | Liquid: organic carbonates, aqueous solutions; Solid: ceramics, polymers [18] [16] |

| Separator | Physical barrier preventing electrical shorting | Porosity, mechanical strength, electrolyte wettability, chemical inertness | Polyolefins (PP/PE), glass fiber, ceramic-coated membranes [18] |

| Current Collectors | Electron transfer between electrodes and external circuit | High electrical conductivity, corrosion resistance, mechanical strength | Aluminum (cathode), copper (anode), stainless steel [18] |

| Salt Bridge | Maintains electrical neutrality between half-cells | Ionic conductivity, minimal junction potential | Agar gel saturated with KNO₃ or KCl [15] |

The Researcher's Toolkit: Essential Materials and Reagents

Table 2: Research Reagent Solutions for Electrochemical Experimentation

| Reagent/Material | Function | Application Examples | Technical Considerations |

|---|---|---|---|

| Proton Exchange Membrane (PEM) | Selective proton conductor, gas separator | Electrochemical hydrogen compressors, fuel cells | Thickness, proton conductivity, mechanical strength at high pressures [16] |

| Metal Foils (Li, Na, Mg, Ca) | Counter/reference electrodes in half-cells | Battery material testing, electrolyte development | Reactivity with electrolytes, purity requirements, plating/stripping efficiency [18] |

| Nonaqueous Electrolytes | Ion transport in non-aqueous systems | Lithium-ion and post-Li batteries | Salt concentration, solvent purity, moisture content, additive packages [18] |

| Electrocatalysts (Pt, bimetallics) | Facilitate redox reaction kinetics | Hydrogen oxidation/evolution, oxygen reduction | Loading, dispersion, support material, poisoning resistance [16] |

| Electrode Formulation Components | Create functional composite electrodes | Battery and fuel cell testing | Binder type (PVDF, PTFE), conductive additive (carbon black), active material ratio [18] |

Electrochemical Cell Configurations and Testing Methodologies

Laboratory-Scale Cell Designs

Research-scale electrochemical cells come in several configurations, each with distinct advantages for specific applications:

- Beaker Cells: Use standard labware, easy to assemble, compatible with large reference electrodes and Luggin capillaries for minimal ohmic drop. Disadvantages include high electrolyte requirements, absence of stack pressure, and need for glovebox containment [18].

- Swagelok Cells: Utilize gas tubing fittings as cell body with plungers as current collectors. Enable easy construction with manually applied spring pressure during assembly. Accommodate three-electrode configurations with specially machined plungers for reference electrodes [18].

- Coin Cells: Feature compact, crimped design with polypropylene gaskets for electrical insulation and air tightness. Ideal for long-term cycling with minimal electrolyte volume. Three-electrode configurations require modification and can compromise sealing reliability [18].

Experimental Protocol: Half-Cell Voltage Measurement

Objective: To construct and measure the voltage of electrochemical cells involving different half-reactions and determine their relative positions in a Table of Standard Potentials [15].

Materials and Equipment:

- Voltmeter with high impedance input

- Electrode materials (copper wire, platinum or carbon inert electrodes)

- Salt bridge (glass tube filled with gel saturated with strong electrolyte such as KNO₃)

- Solutions of varying concentrations (Cu²⁺, Fe³⁺/Fe²⁺)

- Proper waste containers for metal solutions [15]

Methodology:

- Construct two electrode-compartments, each containing an electrode and the constituents of the half-reaction

- For half-reactions where the electrode participates directly (e.g., Cu²⁺/Cu), use the metal wire electrode

- For inert electrodes (e.g., Fe³⁺/Fe²⁺), use platinum or carbon electrodes to prevent competing reactions

- Connect compartments via salt bridge to maintain electrical neutrality while preventing solution mixing

- Measure cell voltage magnitude and polarity, noting electron flow from red (positive, cathode) to black (negative, anode) leads

- Record measurements for multiple concentration combinations

- Analyze results using Nernst equation for non-standard conditions [15]

Technical Notes:

- The experiment is conceptually straightforward but requires careful interpretation during data analysis

- Begin analysis while in laboratory to facilitate repetition of confusing steps or consultation with colleagues

- Temperature assumptions (typically 25°C) must be consistent throughout calculations [15]

Advanced Applications in Sustainable Energy Systems

Electrochemical Hydrogen Compression Systems

Electrochemical hydrogen compressors (EHCs) represent an innovative sustainable technology that applies fundamental electrochemical principles to hydrogen compression needs. EHCs operate through three fundamental stages:

- Low-pressure hydrogen oxidation: Gaseous H₂ is supplied to the anode, where it oxidizes in the presence of an electrocatalyst (typically platinum), splitting into protons (H⁺) and electrons (e⁻) [16]

- Selective proton transport: Protons migrate through a proton exchange membrane while electrons travel through an external circuit. The membrane acts as a selective barrier, enabling simultaneous hydrogen purification [16]

- High-pressure hydrogen evolution: At the cathode, protons and electrons recombine to form H₂ at elevated pressures, ranging from 30-130 bar in lab systems to 875 bar in commercial prototypes [16]

The complete operational workflow of an electrochemical hydrogen compressor is visualized below:

Sustainable Energy Research Priorities

The NSF Electrochemical Systems program emphasizes fundamental engineering science research that enables innovative processes for sustainable energy applications. Key research priorities include:

- Advanced battery systems: High-energy and high-power density batteries beyond lithium-ion, including metal anodes, solid-state electrolytes, multivalent chemistries (Na, K, Mg, Ca) for transportation and renewable energy storage [17] [18]

- Electrochemical production systems: Novel processes for chemical production with improved process intensification, modularization, energy efficiency, and reduced environmental footprint [17]

- Flow battery technologies: Alternative redox chemistries (organic, inorganic, organometallic) and operating strategies for stationary energy storage applications [17]

- Solar fuel generation: Photocatalytic or photoelectrochemical processes for water splitting to hydrogen gas or carbon dioxide reduction to fuels [17]

Research proposals must address how successful work will improve process realization and economic feasibility while comparing proposed work against current state of the art [17].

Electrochemical cell components form integrated systems where each element plays a distinct yet interconnected role in determining overall device performance. The advancement of sustainable electrochemical systems depends on fundamental understanding of component-level properties and their interactions at molecular, meso, and system scales. Research focusing on novel materials, advanced chemistries beyond lithium-ion, and innovative cell designs will continue to drive progress toward sustainable energy storage and conversion technologies that reduce greenhouse gas production and utilize renewable resources [17]. The integration of experimental and theoretical approaches, coupled with systematic electrochemical testing protocols, provides the foundation for developing the next generation of electrochemical technologies essential for global decarbonization efforts.

Innovative Electro-Synthetic Methods for Drug Molecule Assembly

The activation of thermodynamically stable and inert molecules represents a fundamental challenge in advancing sustainable chemical processes. Traditional industrial methods often rely on extreme temperatures and pressures, consuming substantial energy and generating significant greenhouse gas emissions. Electrochemistry offers an alternative pathway, using electrical current to drive chemical reactions under ambient conditions. This approach is particularly valuable for activating inert molecules like nitrogen (N₂) and carbon dioxide (CO₂), which is crucial for developing decentralized and environmentally friendly synthesis technologies for essential chemicals such as ammonia and pharmaceutical precursors [19] [20].

Framed within sustainable electrochemical systems, this whitepaper delves into the core principles, strategies, and methodologies enabling the electrochemical activation of inert molecules. It provides a technical guide for researchers and scientists, detailing effective activation strategies, standardized experimental protocols, and advanced computational tools that are pushing the boundaries of what is possible in green chemistry and sustainable drug development.

Effective N2 Activation Strategies

The electrochemical reduction of nitrogen (N₂) to ammonia (NH₃) is a promising alternative to the energy-intensive Haber-Bosch process. However, its development is substantially hindered by the high dissociation energy of the N≡N triple bond (941 kJ·mol⁻¹), low N₂ solubility in aqueous solutions, and strong competition from the hydrogen evolution reaction (HER) [19]. To overcome these limitations, researchers have developed innovative strategies that first convert inert N₂ into reactive intermediates.

Li/Ca-Mediated Activation

This approach leverages the unique properties of lithium or calcium metals to spontaneously cleave the N≡N bond. These mediators react with N₂ to form metal-nitrogen intermediates (such as LiₓNᵧH₂ or CaₓNᵧH₂), which are high-energy compounds that subsequently react readily with a proton source to generate NH₃ [19]. The lithium-mediated process, in particular, has been shown to operate efficiently at ambient pressure and has achieved high current densities and Faradaic efficiencies in flow reactor configurations [19].

Challenges and Perspectives: Key challenges include electrolyte acidification from anode reactions and the continuous consumption of the lithium metal mediator. Future research is focused on developing stable, lithium-conducting solid electrolyte interfaces (SEI) and optimizing reactor designs, such as flow cells, to improve the process's efficiency and scalability [19].

Plasma-Assisted Activation

Plasma technology provides a non-thermal method to activate N₂ by converting it into more reactive nitrogen oxides (NOₓ⁻). These species can then be electrochemically reduced to NH₃ with high selectivity, potentially reaching efficiencies of approximately 90% [19]. This method decouples the challenging N₂ activation step from the NH₃ synthesis step, allowing each to be optimized independently.

Challenges and Perspectives: The primary hurdles involve the high energy cost of generating plasma and the integration of plasma generation with electrochemical reduction systems. Research is ongoing to develop more energy-efficient plasma sources and to design synergistic reactor configurations that enhance overall energy efficiency [19].

Table 1: Comparison of Electrochemical N₂ Activation Strategies for NH₃ Synthesis

| Strategy | Mechanism | Key Intermediate | Reported NH₃ Selectivity | Primary Challenges |

|---|---|---|---|---|

| Li/Ca-Mediated | Chemical cleavage of N₂ by Li/Ca metal | LiₓNᵧH₂, CaₓNᵧH₂ | High current densities achieved [19] | Mediator consumption, electrolyte acidification |

| Plasma-Assisted | Plasma conversion of N₂ to reactive species | NOₓ⁻ | ~90% [19] | High energy cost of plasma, system integration |

Activation of Other Inert Molecules

The principle of using electricity to activate inert molecules extends beyond nitrogen. Carbon dioxide (CO₂) is another prime target, with electrochemical conversion offering a route to value-added products.

CO₂ to Useful Molecules

Electrochemistry enables the incorporation of inert CO₂ into organic frameworks, a process highly relevant to pharmaceutical development. A collaboration between Cornell and Sichuan University demonstrated the carboxylation of pyridine, a vital heterocycle in FDA-approved drugs. The reaction introduces CO₂ directly into the pyridine ring, changing its functionality and enhancing its ability to bind to biological targets [21].

A critical discovery was that the choice of electrochemical reactor dictates site selectivity. Using an undivided cell led to C4-carboxylation, while a divided cell selectively produced C5-carboxylation. This provides a powerful, controllable method for synthesizing different isomers without changing the catalyst or core reaction conditions [21].

Nature-Inspired Reactor Design

Advancements in reactor engineering are crucial for improving the sustainability and efficiency of these processes. Inspired by the skin structure of desert lizards, researchers have developed innovative flow fields for polymer electrolyte membrane (PEM) systems. This design improves reactant delivery to catalyst layers and enhances water management, supporting high power density in fuel cells and sustained selectivity in CO₂ reduction electrolysers [22].

Experimental Protocols

To ensure reproducible and credible research in electrochemical ammonia synthesis, adhering to standardized protocols is essential, particularly for quantifying low levels of NH₃ and managing contamination.

Benchmarking and Contamination Control

The field has recognized that potential contamination from ambient ammonia, human breath, ion-conducting membranes, or nitrogen-containing compounds in the N₂ stream can severely distort results. Therefore, establishing rigorous benchmarking protocols is mandatory [19].

Standardized Control Experiments:

- ¹⁵N₂ Isotope Labeling: Using ¹⁵N₂ as the feed gas and verifying the production of ¹⁵NH₃ via nuclear magnetic resonance (NMR) is considered the "gold standard" for confirming that ammonia originates from the supplied N₂ and not contaminants [19].

- Purification of Inputs: N₂ gas streams and electrolytes must be rigorously purified to remove any trace nitrogenous contaminants before introduction to the electrochemical cell [19].

- Calibration and Quantification: Multiple calibration methods for NH₃ quantification (e.g., NMR, ion chromatography, spectrophotometric methods) should be used to cross-validate results [19].

Protocol for Lithium-Mediated Ammonia Synthesis

The following provides a detailed methodology for a typical Li-mediated N₂ reduction experiment [19].

- Electrolyte Preparation: Prepare a 0.5 M LiClO₄ solution in anhydrous tetrahydrofuran (THF). Add ethanol (2-5% v/v) as a proton source. The electrolyte must be thoroughly purified and stored under an inert atmosphere to exclude water and oxygen.

- Electrochemical Cell Assembly: Use a sealed, two-compartment (divided) H-cell or a custom flow reactor. A lithium metal foil serves as the working electrode (cathode). The counter electrode (anode) is typically platinum or nickel. A reference electrode (e.g., Ag/Ag⁺) is inserted into the cathode compartment.

- Gas Purging: Purity the electrolyte and cell by purging with an inert gas (e.g., Argon) for at least 30 minutes. Subsequently, switch to a purified ¹⁵N₂ gas stream and maintain a continuous flow throughout the experiment.

- Electrolysis: Apply a constant potential or current density to the working electrode. The typical applied potential is between -2.0 V and -3.0 V vs. Fc/Fc⁺. The reaction is performed at ambient temperature and pressure.

- Product Quantification: After a set duration (e.g., 2-6 hours), collect the electrolyte from the cathode chamber. Analyze the solution for ¹⁵NH₄⁺ using quantitative ¹H NMR spectroscopy against a known internal standard to calculate the Faradaic efficiency and yield.

The Scientist's Toolkit: Computational and Material Aids

Advancing the field requires a combination of advanced computational tools for prediction and high-quality materials for experimentation.

Machine Learning for Energy Prediction

Accurately predicting activation energies is crucial for understanding and designing reactions, but high-level quantum chemistry calculations are computationally expensive. Machine learning (ML) models, particularly Graph Neural Networks (GNNs), are being developed to overcome this.

- Delta Learning: This has emerged as the most effective ML approach. It involves predicting the difference (delta) between low-level semiempirical (SQM) calculations and high-level CCSD(T)-F12a activation energies. This method achieves high accuracy with substantially reduced high-level data requirements, matching performance with only 20–30% of the full data set [23].

- Feature Engineering: This strategy involves adding computed molecular properties (e.g., thermodynamic data from low-level methods) as input features to the model to improve its predictive performance [23].

- Software Tools: The Chemprop model is a state-of-the-art GNN that uses a directed-message passing neural network (D-MPNN) and the Condensed Graph of Reaction (CGR) representation to effectively predict reaction properties from SMILES strings [23].

Table 2: Essential Research Reagents and Materials for Featured Experiments

| Reagent/Material | Function in Experiment | Example Application |

|---|---|---|

| Lithium Perchlorate (LiClO₄) | Supporting electrolyte; provides Li⁺ ions for N₂ cleavage. | Li-mediated N₂ reduction [19] |

| Ethanol (EtOH) | Proton source in non-aqueous electrolytes. | Li-mediated N₂ reduction [19] |

| Tetrahydrofuran (THF) | Anhydrous, aprotic solvent for Li-based systems. | Li-mediated N₂ reduction [19] |

| ¹⁵N₂ Isotope Gas | Labeled feedstock for verifying N₂ reduction versus contamination. | Quantitative isotopic verification of NH₃ synthesis [19] |

| Lithium Metal Foil | Working electrode and chemical mediator for N₂ activation. | Li-mediated N₂ reduction [19] |

| Ru-dispersed Cu Nanowire | Electrocatalyst for selective reduction of nitrogenous species. | High-efficiency conversion of NO₃⁻ to NH₃ [19] |

Reactor Selection Guide

The physical design of the electrochemical cell is a critical, often overlooked, variable.

- Divided Cell: Features a physical separator (e.g., porous glass frit or ion-exchange membrane) that isolates the anode and cathode compartments. This prevents re-oxidation of products and allows for different chemical environments in each half-cell. It is often essential for achieving high Faradaic efficiency [19] [21].

- Undivided Cell: The anode and cathode are in the same chamber. While simpler to construct and offering lower resistance, it can lead to cross-talk between electrode reactions. Notably, it can be used strategically to alter product selectivity, as demonstrated in the carboxylation of pyridines [21].

The electrochemical activation of inert molecules like N₂ and CO₂ has evolved from a conceptual idea to a rapidly advancing field with tangible pathways to sustainable chemical production. Strategies such as Li-mediated reactions and plasma activation effectively lower the kinetic barriers for N₂ fixation, while reactor engineering and machine learning provide powerful tools to optimize selectivity and efficiency. For the pharmaceutical industry, electrochemistry offers new routes to incorporate inert building blocks like CO₂ into complex drug precursors with precise control.

While challenges in scalability, energy efficiency, and cost remain, the convergence of advanced materials, innovative reactor design, and computational intelligence is creating a robust foundation for the future. Continued interdisciplinary collaboration will be essential to translate these laboratory successes into industrial-scale processes, ultimately contributing significantly to global sustainability goals by decarbonizing the chemical sector [20].

Cross-Electrophile Coupling for Carbon-Carbon Bond Formation

Cross-electrophile coupling (XEC) represents a transformative approach in modern organic synthesis, enabling the direct formation of carbon-carbon bonds from two distinct electrophilic precursors. This methodology circumvents the longstanding requirement for preformed carbon nucleophiles—such as organomagnesium (Grignard) or organoboron reagents—which often present challenges related to their stability, commercial availability, and compatibility with functional groups [24]. The development of XEC is particularly relevant within sustainable electrochemical systems, as it aligns with principles of atom economy and step efficiency by utilizing stable, readily available electrophilic building blocks.

The central challenge in XEC is achieving cross-selectivity—effectively promoting the reaction between two different electrophiles while minimizing the formation of symmetric dimer byproducts [24] [25]. This article provides a comprehensive technical examination of XEC mechanisms, catalytic systems, and experimental methodologies, with particular emphasis on recent advances in first-row transition metal catalysis that enhance sustainability profiles in pharmaceutical and materials chemistry.

Fundamental Principles and Selectivity Challenges

The Core Selectivity Problem

In conventional cross-coupling reactions, selectivity is inherently governed by the differential reactivity patterns of nucleophiles and electrophiles. Nucleophiles typically engage with the metal catalyst through transmetalation, while electrophiles undergo oxidative addition [24]. In XEC, however, both coupling partners are electrophiles, creating a scenario where both components compete for similar reaction pathways with the catalyst, leading to three potential coupling products: the desired cross-coupled product along with two symmetric dimers (Figure 1) [26].

Strategies for Achieving Cross-Selectivity

Researchers have developed several strategic approaches to overcome selectivity challenges in XEC:

Employing an Excess of One Reagent: When electrophiles exhibit similar reactivity, using excess of one partner can drive the reaction toward the cross-coupled product. This approach is mathematically feasible, with theoretical yields reaching 66% with a 2:1 reagent ratio and 75% with a 3:1 ratio in fully reversible systems [24]. This strategy proves particularly useful when one electrophile is inexpensive or when symmetric dimers can be readily separated [24].

Electronic Differentiation of Starting Materials: Leveraging inherent reactivity differences between electrophile classes represents a more sophisticated approach. For instance, aryl halides and alkyl halides demonstrate distinct oxidative addition pathways with transition metal catalysts—aryl halides typically undergo concerted oxidative addition to low-valent metals, while alkyl halides frequently proceed through radical pathways [25] [26]. This differential reactivity enables sequential oxidative addition processes that favor cross-product formation.

Steric Differentiation: In systems with electronically similar substrates, steric properties of both catalyst and substrates can influence selectivity. Bulky ligands on metal catalysts may preferentially accommodate one substrate over another based on steric matching, thereby directing the coupling pathway [24].

Radical-Chain Processes: Certain nickel-catalyzed XEC reactions proceed through radical-chain mechanisms where selectivity arises from the preferential oxidative addition of aryl halides to nickel(0) and the propensity of alkyl halides to form free radicals. These radicals then intercept aryl-nickel intermediates, leading to cross-selectivity [26].

Mechanism and Catalytic Systems

Nickel-Catalyzed Mechanisms

Nickel catalysis has proven exceptionally versatile in XEC transformations, with several distinct mechanistic pathways identified:

Sequential Oxidative Addition Mechanism: This pathway involves stepwise engagement of two different electrophiles with the nickel catalyst. A representative mechanism for coupling benzyl bromide with phenylacetyl chloride begins with oxidative addition of benzyl bromide to Ni(0) species 7, forming Ni(II) complex 8. This intermediate is reduced to anionic Ni(0) complex 9, which selectively reacts with the acid chloride 2 through oxidative addition. Reductive elimination then yields the cross-coupled ketone product 3 while regenerating the active catalyst (Figure 2) [24].

Radical-Chain Mechanism: For couplings between aryl halides and alkyl halides, a radical-chain process often operates. The catalytic cycle initiates with oxidative addition of the aryl halide to Ni(0), forming an aryl-Ni(II) species. Concurrently, alkyl halides generate alkyl radicals through single-electron transfer processes. The aryl-Ni(II) complex captures the alkyl radical, forming a diarylalkyl-Ni(III) intermediate that undergoes reductive elimination to yield the cross-coupled product and a Ni(I) species. The Ni(I) intermediate then propagates the chain by reducing another alkyl halide molecule to generate an alkyl radical while regenerating the Ni(0) catalyst (Figure 3) [25] [26].

Table 1: Comparison of Nickel-Catalyzed XEC Conditions for Aryl-Alkyl Coupling [26]

| Entry | Substrate Combination | Yield (%) with Mn Reductant | Yield (%) with Zn Reductant | Key Reaction Features |

|---|---|---|---|---|

| 1 | Ar–I + I–alkyl | 88 | 49 | Superior with Mn reductant |

| 2 | Ar–Br + Br–alkyl | 65 | 77 | Superior with Zn reductant |

| 3 | Ar–Br + I–alkyl | 77 | 45 | Mixed halide system |

| 4 | Ar–I + Br–alkyl | 81 | 58 | Mixed halide system |

Emerging Iron Catalysis

Recent advances in iron-catalyzed XEC present sustainable alternatives to precious metal systems. Iron offers significant advantages including natural abundance, low toxicity, and cost-effectiveness [27]. However, developing iron-based XEC systems has faced challenges due to the limited ability of iron complexes to undergo oxidative addition with stubborn electrophiles like chlorides [27] [28].

A breakthrough protocol demonstrated that iron(II) species, when combined with B₂pin₂ (bis(pinacolato)diboron) as a reductant, can generate highly reactive iron(0) species capable of activating both aryl chlorides and unactivated alkyl chlorides [27] [28]. Experimental and computational studies support a mechanism involving Li cation-assisted single-electron transfer (CASET), where synergy between iron and lithium enhances alkyl radical generation through Li-Cl interactions [27]. This system exhibits remarkable functional group tolerance and achieves yields up to 81% for C(sp²)-C(sp³) bond formation (Figure 4) [27].

Experimental Protocols

Iron-Catalyzed Cross-Electrophile Coupling of Aryl Chlorides with Alkyl Chlorides

This protocol details the coupling of 4-chloro-1,1′-biphenyl with 1-chloro-4-methoxybutane using an iron/B₂pin₂ catalytic system [27]:

Step 1: Reaction Setup

- In an 8 mL glass vial equipped with a magnetic stir bar, combine in a glove box:

- FeBr₂ (3.1 mg, 0.014 mmol, 7 mol %)

- B₂pin₂ (126.9 mg, 0.5 mmol, 2.5 equiv)

- LiOMe (41.8 mg, 1.1 mmol, 5.5 equiv)

- NaI (40.5 mg, 0.27 mmol, 1.35 equiv)

- 1-Chloro-4-methoxybutane (42.9 mg, 0.35 mmol, 1.75 equiv)

- 4-Chloro-1,1′-biphenyl (37.7 mg, 0.2 mmol, 1.0 equiv)

- TMEDA (9.7 mg, 0.084 mmol, 42 mol %)

- Freshly distilled MTBE (0.3 mL)

- Seal the vial with a cap containing a PTFE-lined silicone septum and remove from the glove box.

- Secure the vial top with parafilm.

Step 2: Reaction Execution

- Heat the reaction mixture in a heating module at 80°C for 15 hours with continuous stirring.

- Monitor reaction progress by TLC or GC-MS.

Step 3: Workup and Purification

- After cooling to room temperature, dilute the reaction mixture with ethyl acetate (10 mL).

- Wash with water (5 mL) and brine (5 mL).

- Dry the organic layer over anhydrous Na₂SO₄, filter, and concentrate under reduced pressure.

- Purify the crude product by flash column chromatography on silica gel (eluent: hexane/ethyl acetate) to obtain 4-(4-methoxybutyl)-1,1′-biphenyl as a colorless oil (38 mg, 81% yield).

Critical Notes:

- LiOMe cannot be replaced by other bases (t-BuOLi, t-BuONa, t-BuOK, MeONa, or MeOK) in this system.

- The reaction exhibits scalability, with successful demonstrations on gram-scale syntheses.

- The system tolerates diverse functional groups, including ethers, esters, and heterocycles.

Adaptation for Heteroaryl Chlorides

For coupling heteroaryl chlorides (e.g., 3-chloropyridine) with alkyl chlorides, modified conditions are employed [27]:

- Use FeCl₂ (2.5 mg, 0.02 mmol, 10 mol %) as catalyst

- Include cataCXium AHI (9.7 mg, 0.02 mmol, 10 mol %) as ligand

- Adjust stoichiometry: alkyl chloride (1.0 equiv), chloropyridine (1.5 equiv)

- Increase MTBE volume to 1.5 mL

- Extend reaction time to 20 hours at 80°C

The Scientist's Toolkit: Essential Research Reagents

Successful implementation of XEC methodologies requires careful selection of catalysts, ligands, reductants, and additives. The following table catalogizes key reagents and their functions in representative XEC transformations:

Table 2: Essential Research Reagents for Cross-Electrophile Coupling

| Reagent Category | Specific Examples | Function in XEC | Application Notes |

|---|---|---|---|

| Transition Metal Catalysts | Ni(I) salts (NiBr₂, NiCl₂), Fe(II) salts (FeBr₂, FeCl₂) | Catalytic center for oxidative addition and radical generation | Fe systems offer sustainability; Ni provides broader substrate scope |

| Ligands | Bipyridine (Bpy), Phenanthroline, CataCXium AHI, TMEDA | Modifies metal reactivity & selectivity; stabilizes intermediates | Bidentate nitrogen ligands crucial for Ni; phosphines for specific Fe systems |

| Reductants | Zn, Mn, B₂pin₂ | Regenerates active low-valent catalyst from higher oxidation states | B₂pin₂ enables Fe(0) generation; Zn/Mn used in Ni catalysis |

| Additives | NaI, LiOMe, LiCl | Enhances reactivity through halide exchange; promotes SET | Iodide aids alkyl bromide activation; lithium cations assist SET |

| Solvents | DMF, NMP, DMPU, MTBE | Provides reaction medium; influences catalyst stability & selectivity | Anhydrous conditions preferred; ethereal solvents for Fe systems |

Sustainability and Future Perspectives

The evolution of XEC methodologies aligns strongly with sustainable chemistry principles, particularly through:

- Abundant Metal Catalysis: The development of iron-catalyzed XEC systems reduces reliance on precious metals, minimizing environmental impact and cost barriers [27] [28].

- Electrochemical Approaches: Integration of electrochemistry provides renewable electrons as reductants, replacing stoichiometric chemical reductants and generating less waste [24].

- Feedstock Utilization: XEC enables valorization of abundant chlorinated hydrocarbons, offering efficient pathways from readily available feedstocks to complex molecules [27].

Future research directions will likely focus on expanding substrate scope to include challenging electrophile pairs, developing enantioselective variants for stereocontructive synthesis, and further optimizing electrochemical systems to enhance energy efficiency and selectivity. The continued mechanistic investigation of both nickel and iron catalytic systems will provide fundamental insights to guide these developments.

Visual Appendix

Diagram 1: Sequential Oxidative Addition Mechanism for Ni-Catalyzed XEC. This diagram illustrates the mechanism for ketone formation from benzyl bromide and phenylacetyl chloride, involving sequential oxidative additions and critical reduction steps [24].

Diagram 2: Radical-Chain Mechanism in Ni-Catalyzed Aryl-Alkyl Coupling. This diagram depicts the radical-chain process for coupling aryl halides with alkyl halides, showing initiation and propagation phases that ensure cross-selectivity [25] [26].

Diagram 3: Iron-Catalyzed XEC with Li CASET Mechanism. This diagram illustrates the iron catalytic cycle for coupling aryl chlorides with alkyl chlorides, highlighting the role of lithium cation-assisted single-electron transfer (CASET) [27] [28].